Information on guide rollers & profiles

All-round service package with guaranteed success

The technical basis for every clever solution is our heavy-duty guide system with guide rollers and guide profiles in various designs. Guide rollers and guide profiles from ALFATEC can absorb high radial and axial loads. ALFATEC components are characterized by an outstanding service life.

Our portfolio of combined rollers and guide profiles has been consistently developed further. Every year, 47,500 ALFATEC guide rollers leave our production facility in Filderstadt.

Stable, robust and low-maintenance – these are our combination castors. The ALFATEC combination castors are available in different versions: standard tiger castors, precision castors for precise applications, higher load capacities with the |X|tra-Strong castors, stainless steel castors, ALFA-Speed castors for fast, low-noise handling and mammoth castors for moving the heaviest loads.

Everything is possible in our modular system – always suitable with the corresponding accessories. Our modular system, consisting of combined rollers, guide profiles and other components such as fastening elements, enables you to design and produce simple and cost-effective solutions. ALFATEC components have the advantage of short delivery times, as almost every item is available from stock.

We are happy to manufacture our components to your specifications and drawings.

Find out more technical details about our guide rollers and profiles here. In our Download Center you will also find extensive documentation on our products, brochures, data sheets, CAD data and much more.

Technical description of guide rollers

Outer ring

Material steel 20CrMnTi, case-hardened Surface hardness 62-2 HRC

Screws

TORX threadlocker DIN 267-28

Polyamide spot coating – no gluing required

Greasing

Our Tiger rollers are greased with grade 3 lithium grease as standard.

Relubrication

Our Tiger rollers from size 060 can be relubricated to extend their service life. The relubrication holes are sealed with M6 threaded plugs.

Delivered without grease nipple. The rollers must be lubricated at the lubrication connections using a grease gun.

Inner ring

Material bearing steel UNI 100Cr6

Hardness 62-2 HRC

Sealing

ZRS seal

Labyrinth/elastomer seal, lubricated for life

Tolerance

Cylindrical roller bearings manufactured to DIN 620

Tolerance class: PN (PO)

Load rating factors according to ISO 76 and ISO 281/1

Bolt diameter: 0 / 0.05 mm

Relubrication recommendation

In standard environments such as industrial buildings or warehouses

regular lubrication at intervals of 6-12 months is sufficient.

External factors such as dirt, moisture, temperature, increased operating times or chemical substances can lead to the interval having to be shortened

Weld-on studs

Material S355 J2G3

good weldability

Operating temperature

general: from – 40°C to +120°C; can be used up to +150°C for short periods

High-temperature bearings: up to +250°C

Note

The running surfaces of our combination castors are manufactured with a crowned design. Rollers with a diameter greater than 100 mm must be dismantled before welding.

Technical description of guide profiles

Standard profiles

Material 18MnNb6

Micro-alloyed fine-grained steel refined with additions of niobium (Nb) and vanadium (V)

high wear resistance

fine-grained structure

very good weldability

all profiles are supplied in fixed lengths

Delivery versions: bright-rolled, fine-finished, sandblasted

maximum profile length: 12 m

Precision profiles

Material 18MnNb6

Micro-alloyed fine-grained steel refined with additions of niobium (Nb) and vanadium (V)

High wear resistance

Fine-grained structure

Very good weldability

all profiles are supplied in fixed lengths

Higher precision due to machined running surfaces

Maximum profile length: 6 m

Mammoth profiles

Material S355 J2G3

Welded together in several parts

machined – on request: one-sided raceway machining possible

Fixed lengths are manufactured to order

Maximum production length: 12 m

Stainless steel profiles

Material 1.4301

Other materials on request

all profiles are supplied in fixed lengths

Maximum profile length: 8 m

|X|tra-Strong Profile

Material 25MnV5mod

|X|tra load-bearing capacity: around 60% more load-bearing capacity

|X|tra accurate: chamber dimension tolerance of 0.2 mm

|X|tra strong: surface pressure of 1060 Mpa

|X|tra durable: no measurable wear

all profiles are supplied in fixed lengths

Maximum profile length: 8.8 m

Welding recommendation:

On the basis of test results, it is recommended that for a crack-resistant and economical

Welding of fillet welds a two-layer design with a fillet weld thickness of 6 mm

to be used.

Special processing

We are happy to manufacture according to customer drawings or specifications on request.

Simply send us the drawing or tell us the desired pitch.

Note

Before use, the running surfaces of the guide profiles must be cleaned and then coated with grease. A standard commercial grease is sufficient.

The running surfaces should not be painted.

Technical description – Accessories

Fastening elements

Material S235JR

Fastening element is connected to the respective tiger roller

Welded as an assembly

Delivery versions:

BQ – Fastening element square

BR – Fastening element rectangular

BW – Mounting bracket

Special design according to customer drawing on request

Clamping brackets

Clamping brackets for U-profiles and precision profiles from

Size 050 to 090

other sizes on request

Easy installation and alignment of guide profiles

Quick and efficient replacement of guide profiles

Distance elements

Material S235JR

Shims are inserted between the fastening element and its construction to adjust the axial play.

Spacer rings can be used to set the axial play on adjustable tiger rollers.

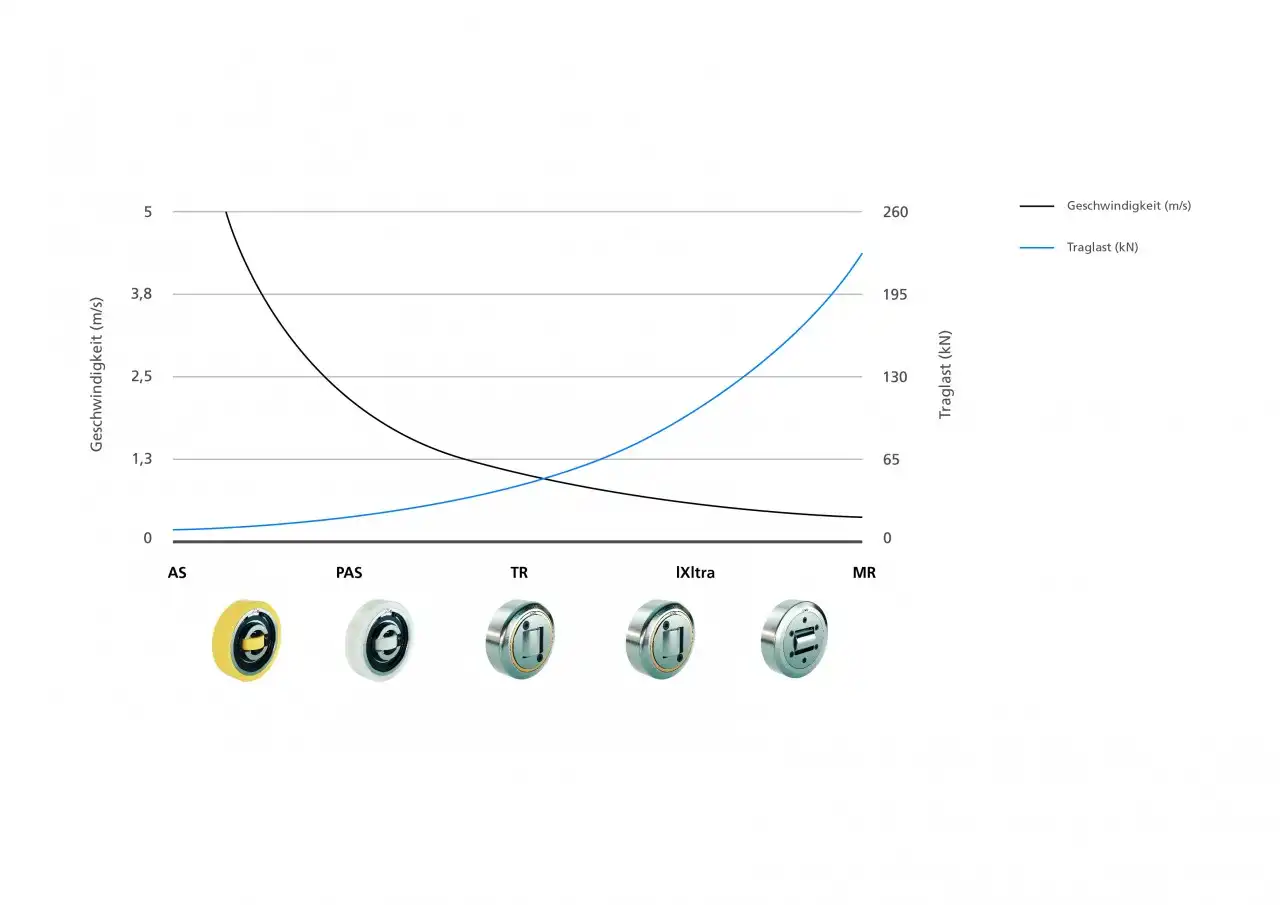

Relationship between speed and load capacity

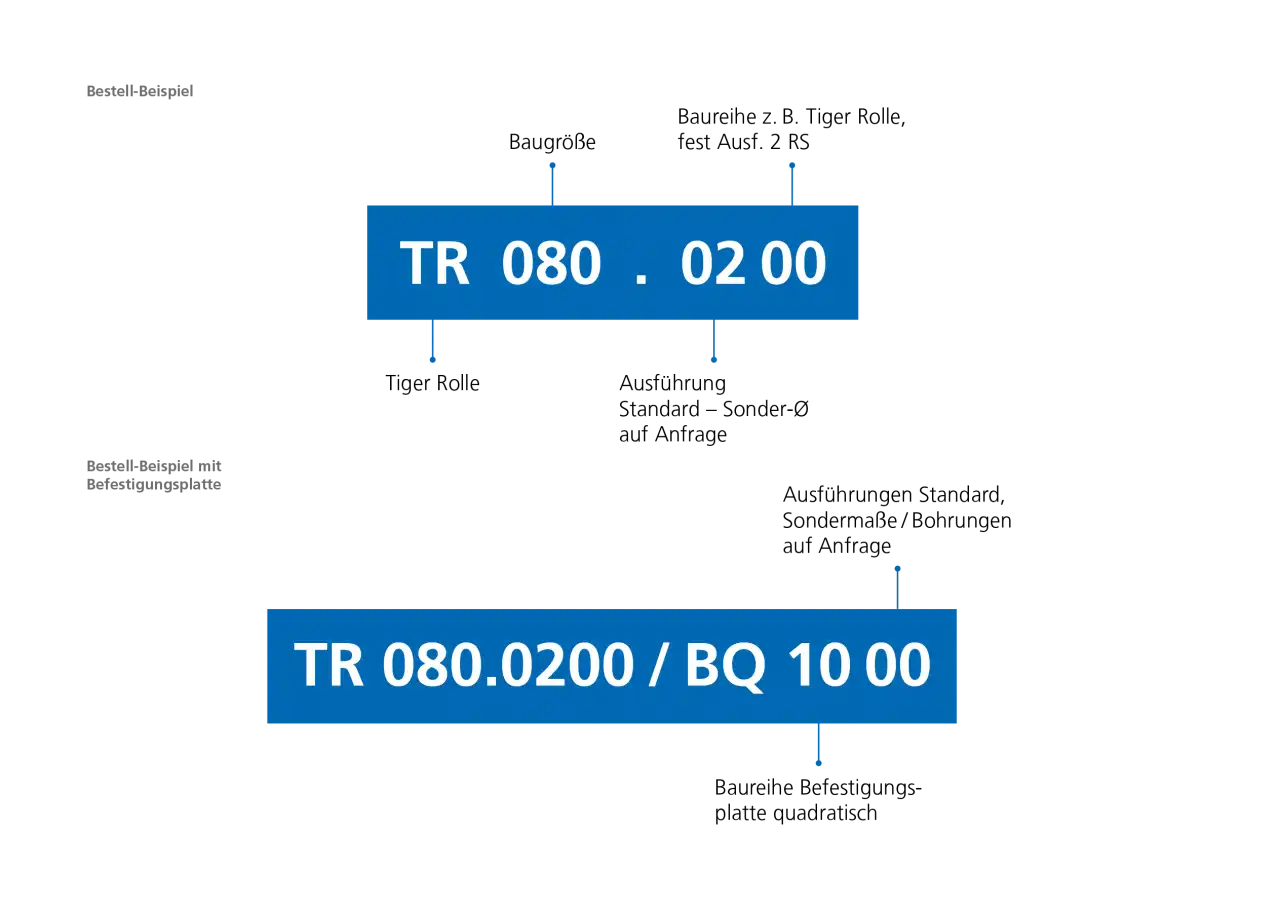

Article description

We are your personal partner from the very first minute.