Individual handling systems

Moving, gripping, turning and lifting heavy loads is precisely our expertise. We prove this with our efficient and ergonomic handling systems. This is because they not only guarantee the safe transportation of loads, but also represent efficient and ergonomic conveyor solutions. This not only allows production processes to be optimized, but also makes work assignments safer and more efficient.

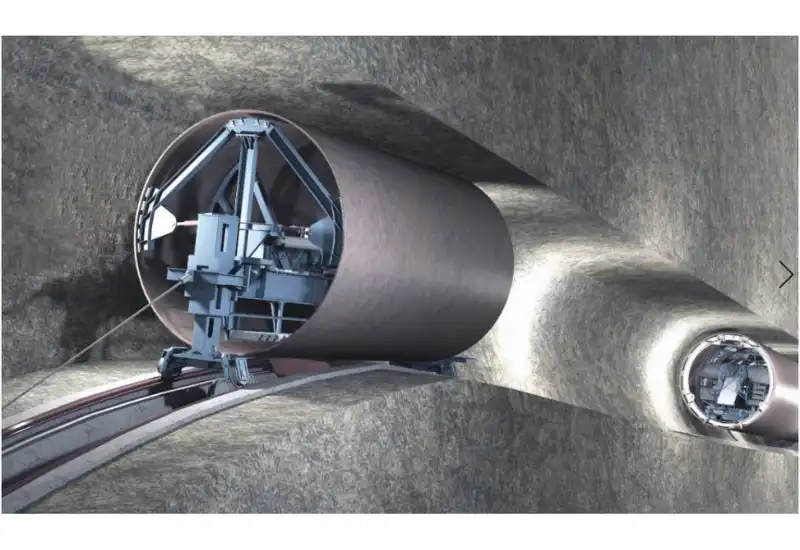

Can’t be done, doesn’t exist

Tight installation space, limited headroom, highly flammable areas – every project brings its own unique challenges. Our handling systems are planned, designed and manufactured specifically for your requirements. We don’t give up until the ideal solution has been found. Dabei sorgen wir für ein effizientes Energiemanagement und implementieren fortschrittliche Antriebstechnik, die sich nahtlos in Ihre spezifischen Produktions- und Logistikprozesse integrieren lässt. Our decades of expertise guarantee you the best possible result: process-optimizing, efficient and economical.

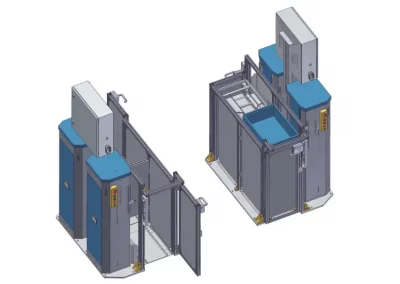

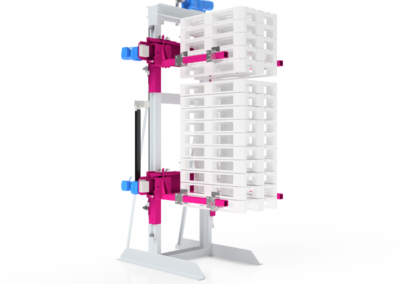

Crate lifter

The ALFATEC crate lifting device enables convenient and efficient work processes. This is because it adapts optimally to individual requirements with many options. The box lifter combines ergonomic and efficient work processes for high payloads of up to 250 kilograms and more. A handling solution that can be used anywhere and at any time – whether in shift operation or as a flexible workstation without a power connection.

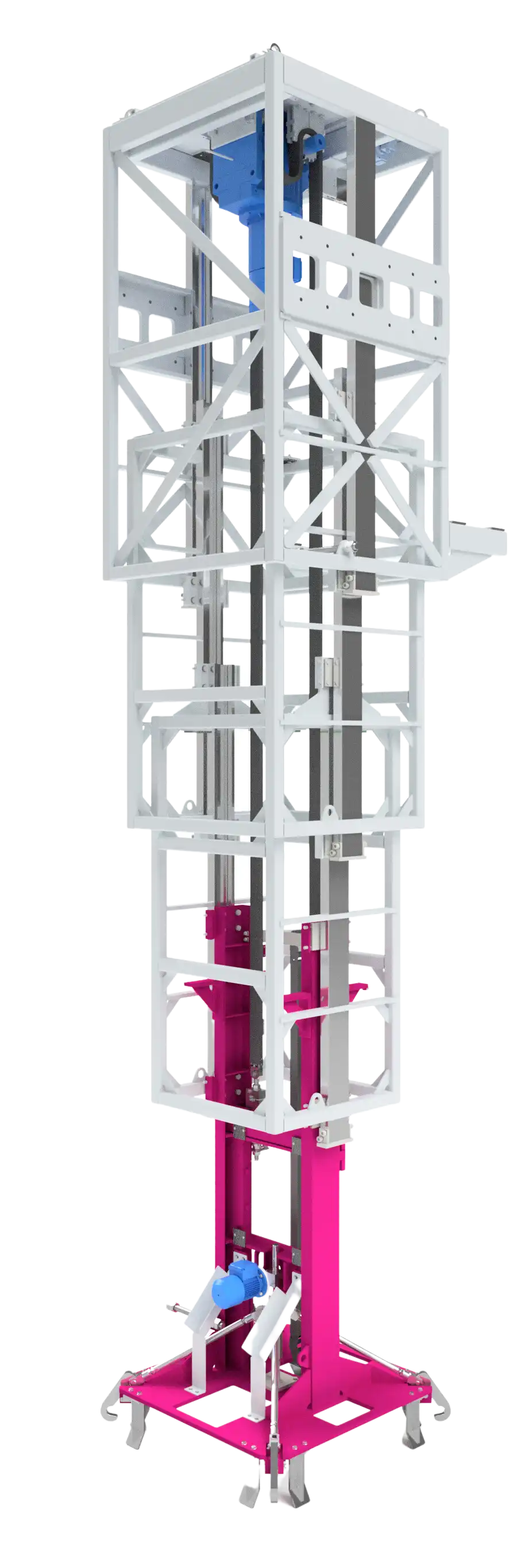

Lifting systems Intralogistics

Lifting and moving heavy loads is part of everyday life in intralogistics. Our intralogistics lifting systems are used to ensure that pallets can be transported safely even at dizzying heights. With the handling technology of our lifting system, high accelerations and high speeds can be realized.

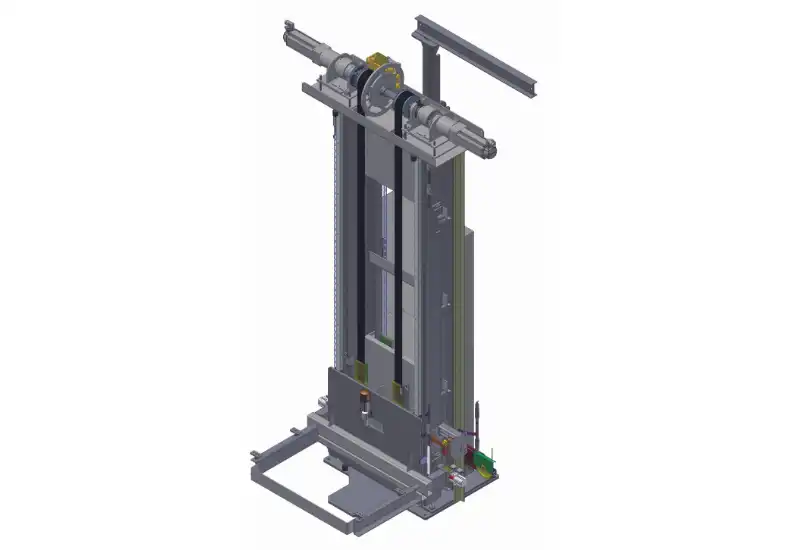

Automotive lifting systems

Our automotive lifting systems are used by all well-known car manufacturers. With the handling technology of our lifting system, different lifting heights and individual loads can be realized with different gripping systems. The different drive types make the lifting systems special and adapt to your requirements.

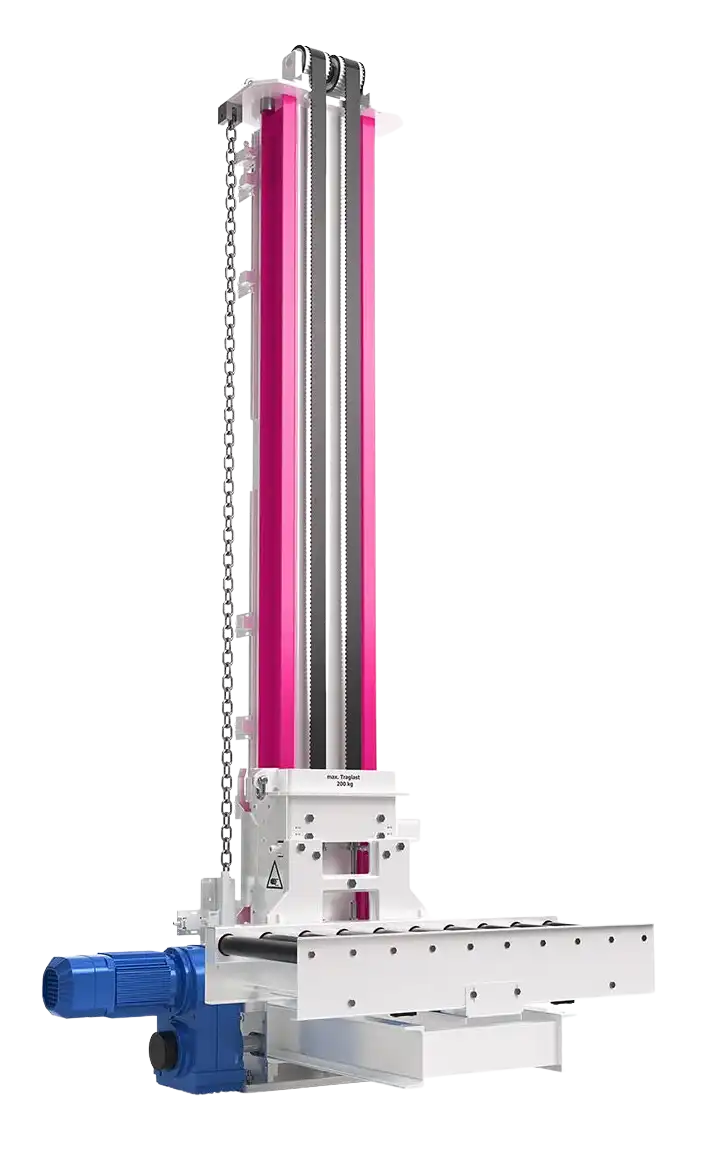

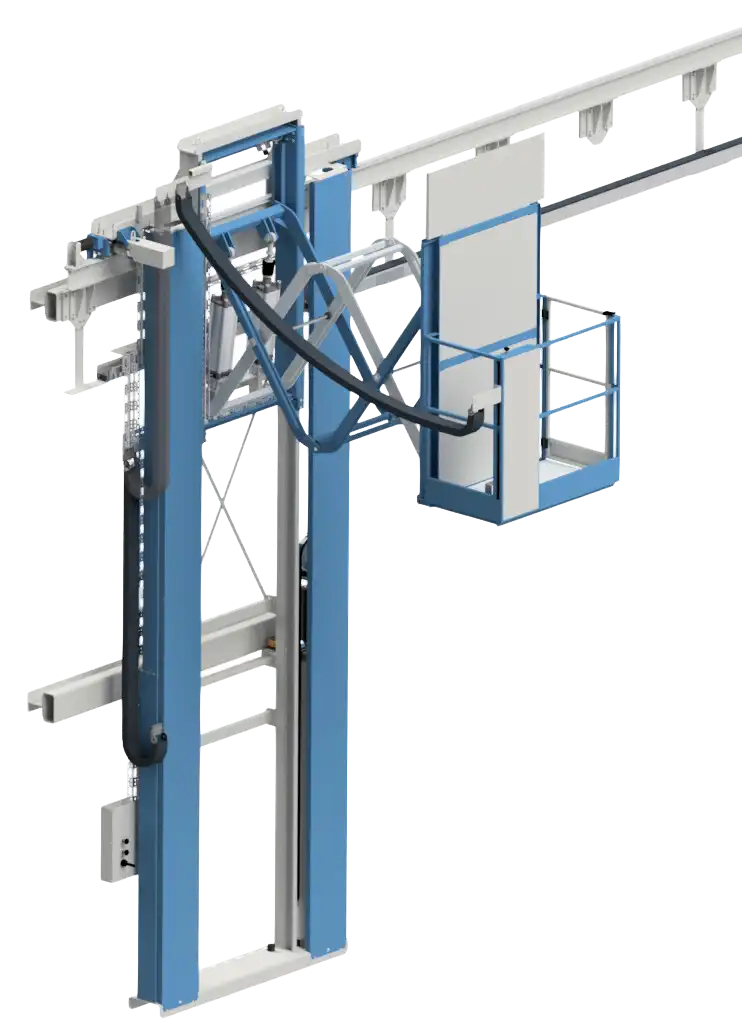

Freight elevator

Our goods elevator is used as a material elevator for unaccompanied vertical transportation of parts. Our goods elevator is easy to operate and offers maximum reliability. The use of our tried-and-tested ALFATEC guide system makes the goods elevator extremely low-maintenance. This avoids unnecessarily long downtimes and maintenance costs. Redundant safety components ensure a safe ride.

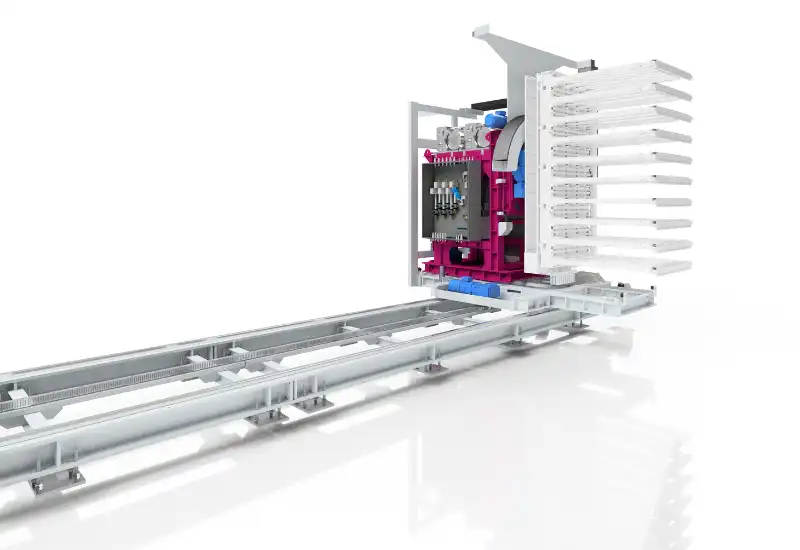

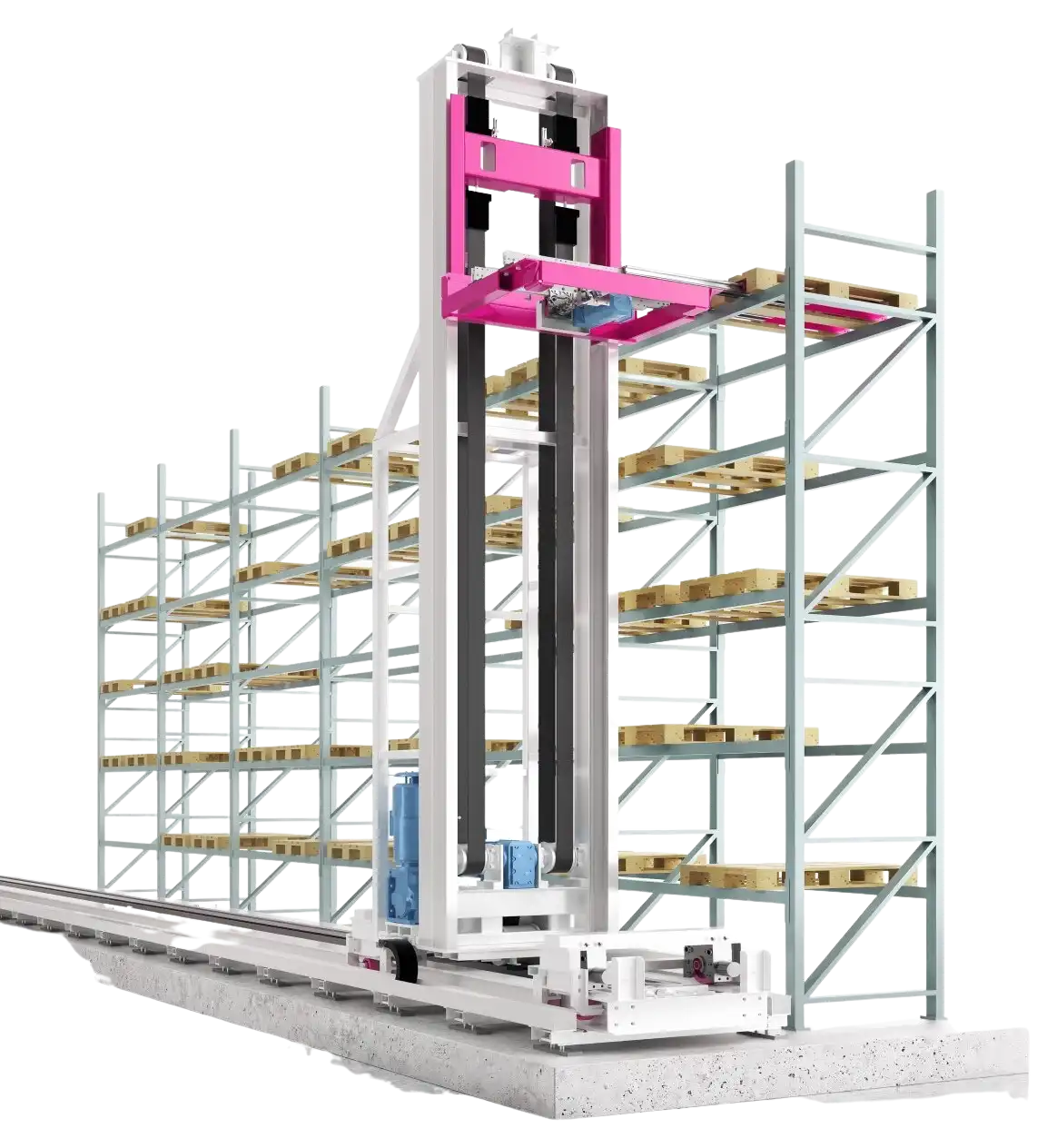

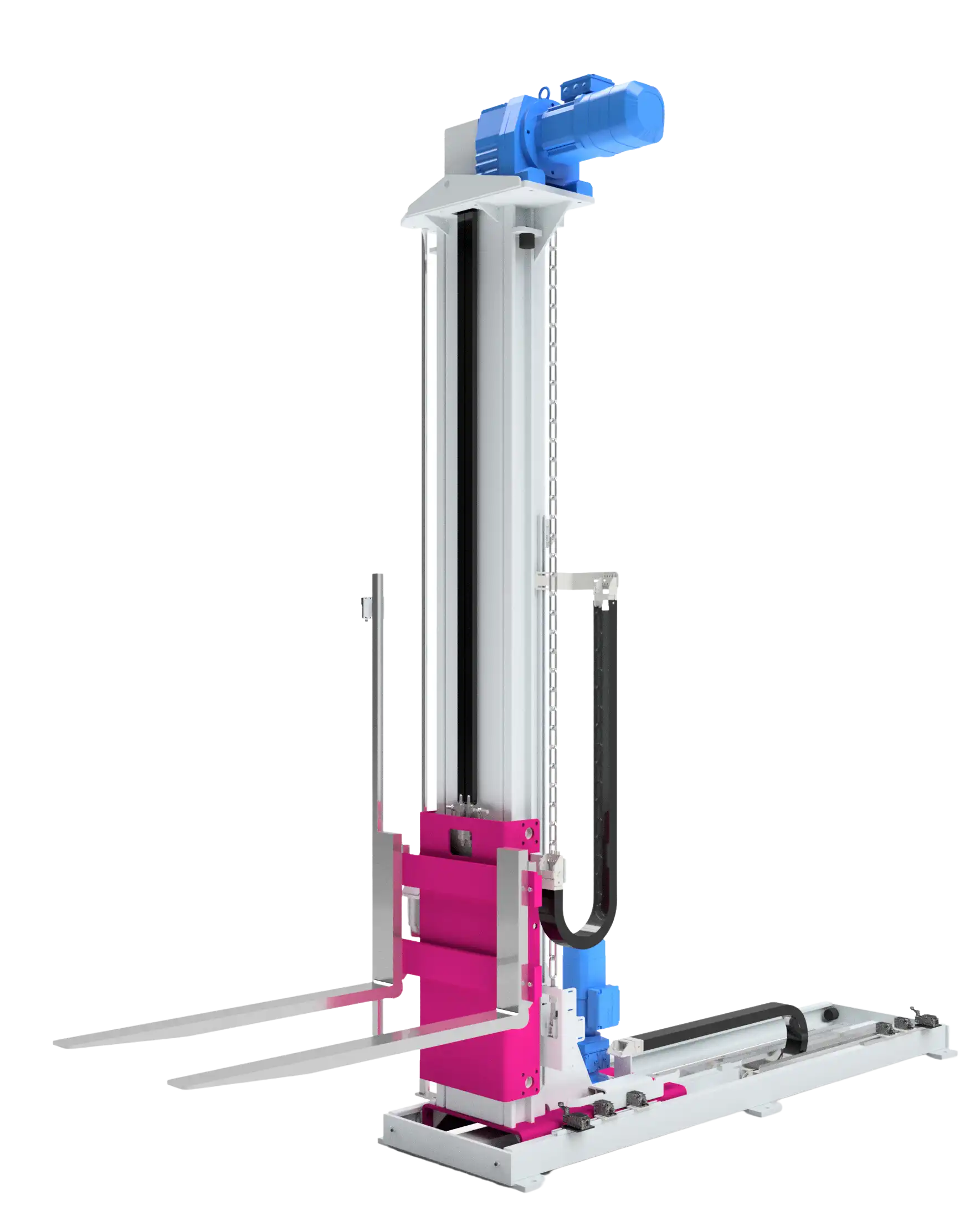

Lifting & driving systems

When a large number of items have to be stored and handled in a limited space, speed and efficiency are essential. In automated high-bay warehouses, our storage and retrieval machines (SRMs) ensure fast and precise storage and retrieval of goods.

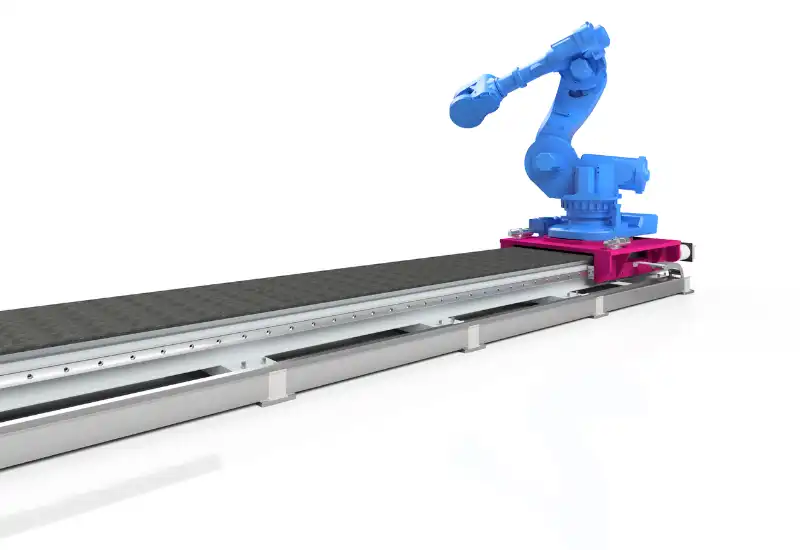

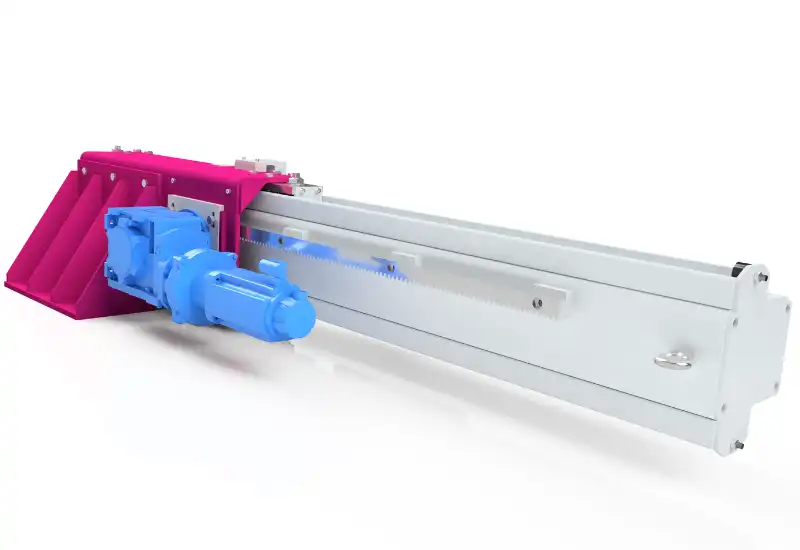

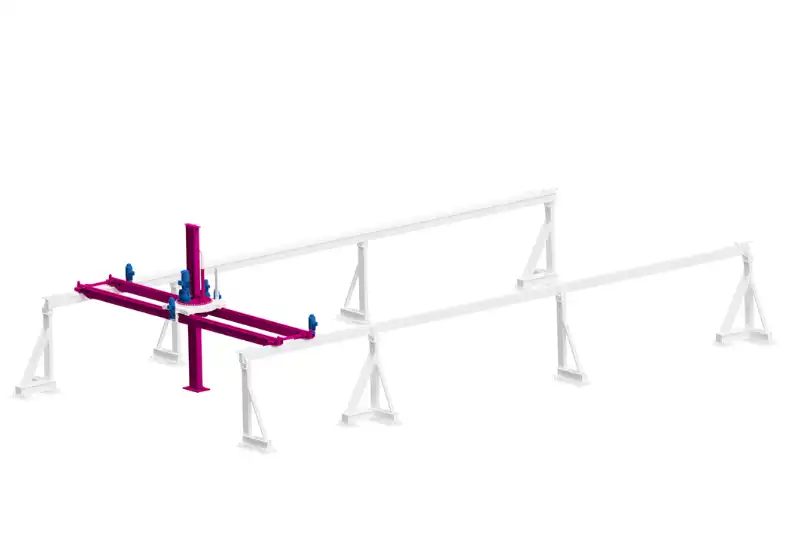

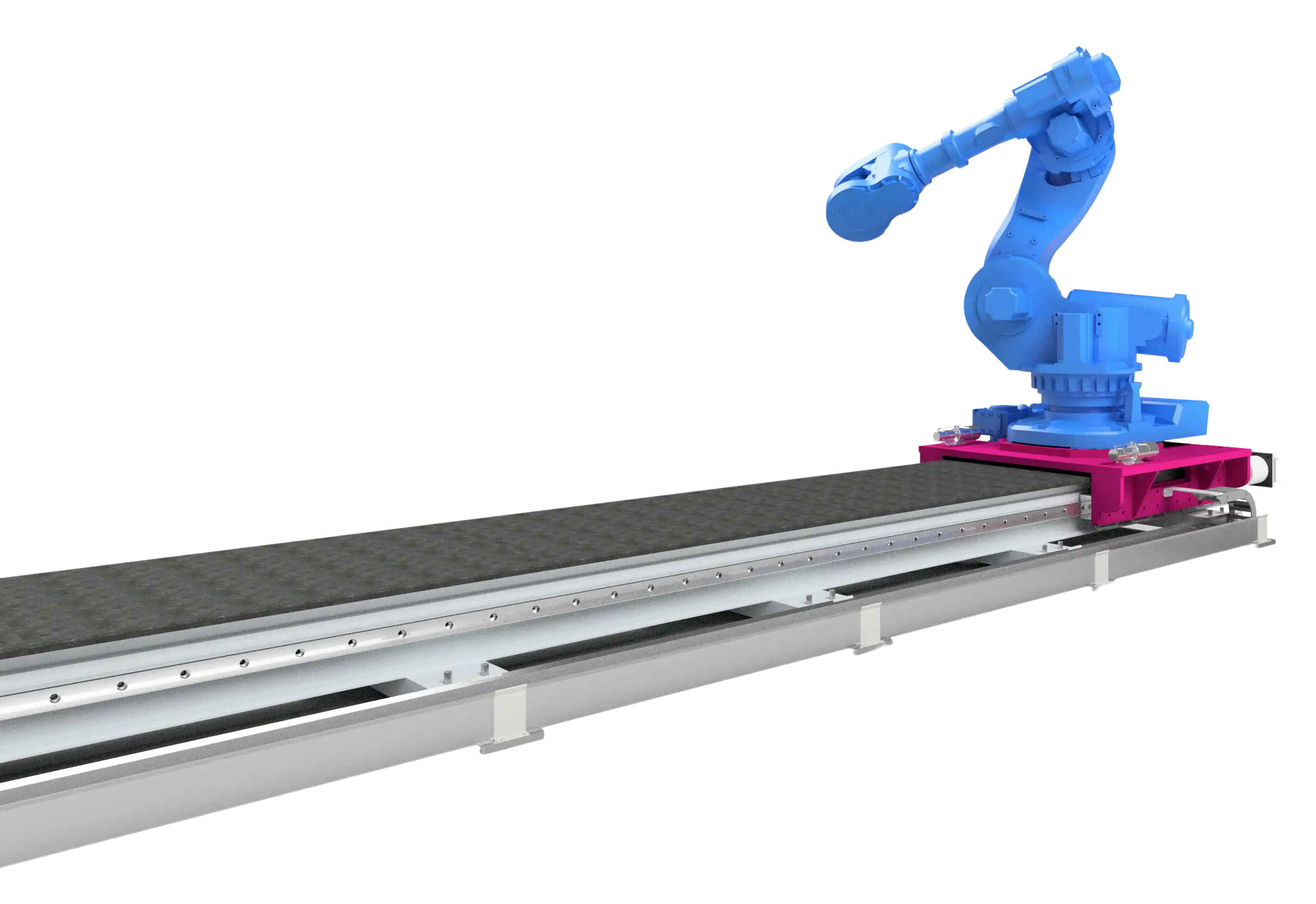

Linear units

Our linear system with our proven ALFATEC guide rollers and profiles is designed for high speeds and moves your heavy loads quickly and precisely. our linear units are characterized by high-precision positioning – the dynamic solution for your robotic application. Can be used as a robust robot axis in combination with 6-axis industrial robots. In the heavy-duty linear unit version (SLE), our linear unit is designed for high loads.

Painting lifting platform

Our pneumatic elevating work platform is ideally suited for use in hazardous and highly flammable areas of painting applications. The painting access platform is designed in the corresponding ATEX or explosion protection area to suit your hazardous substances. The painting aerial work platform impresses with its versatility and is suitable for painting applications, blasting, masking or sanding work.

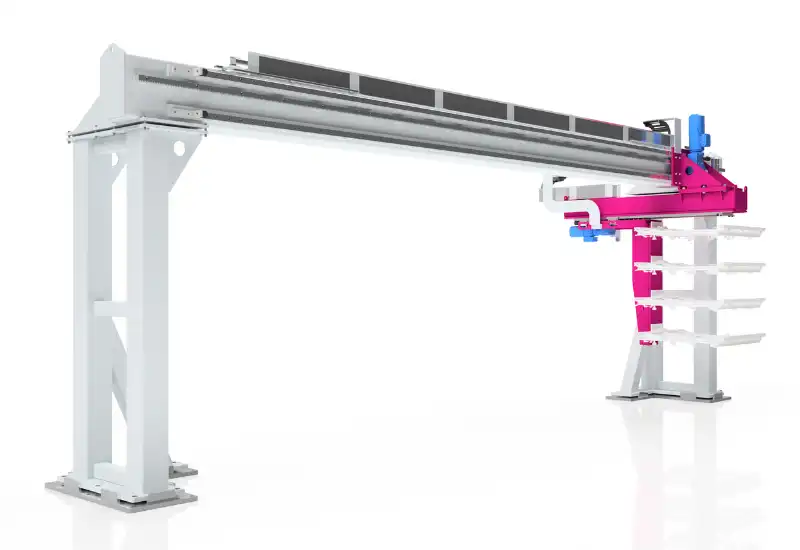

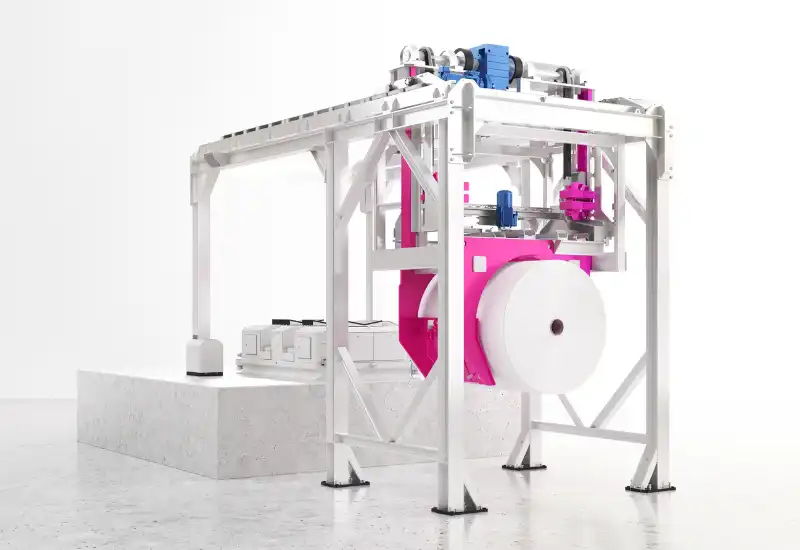

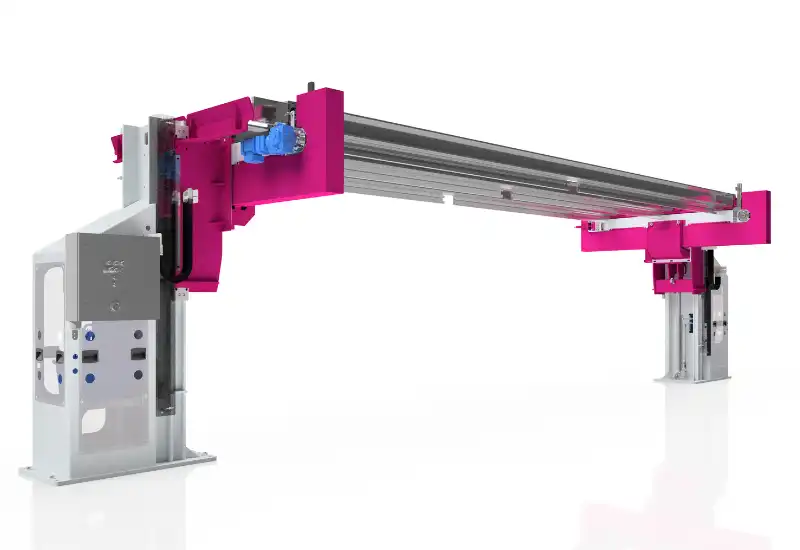

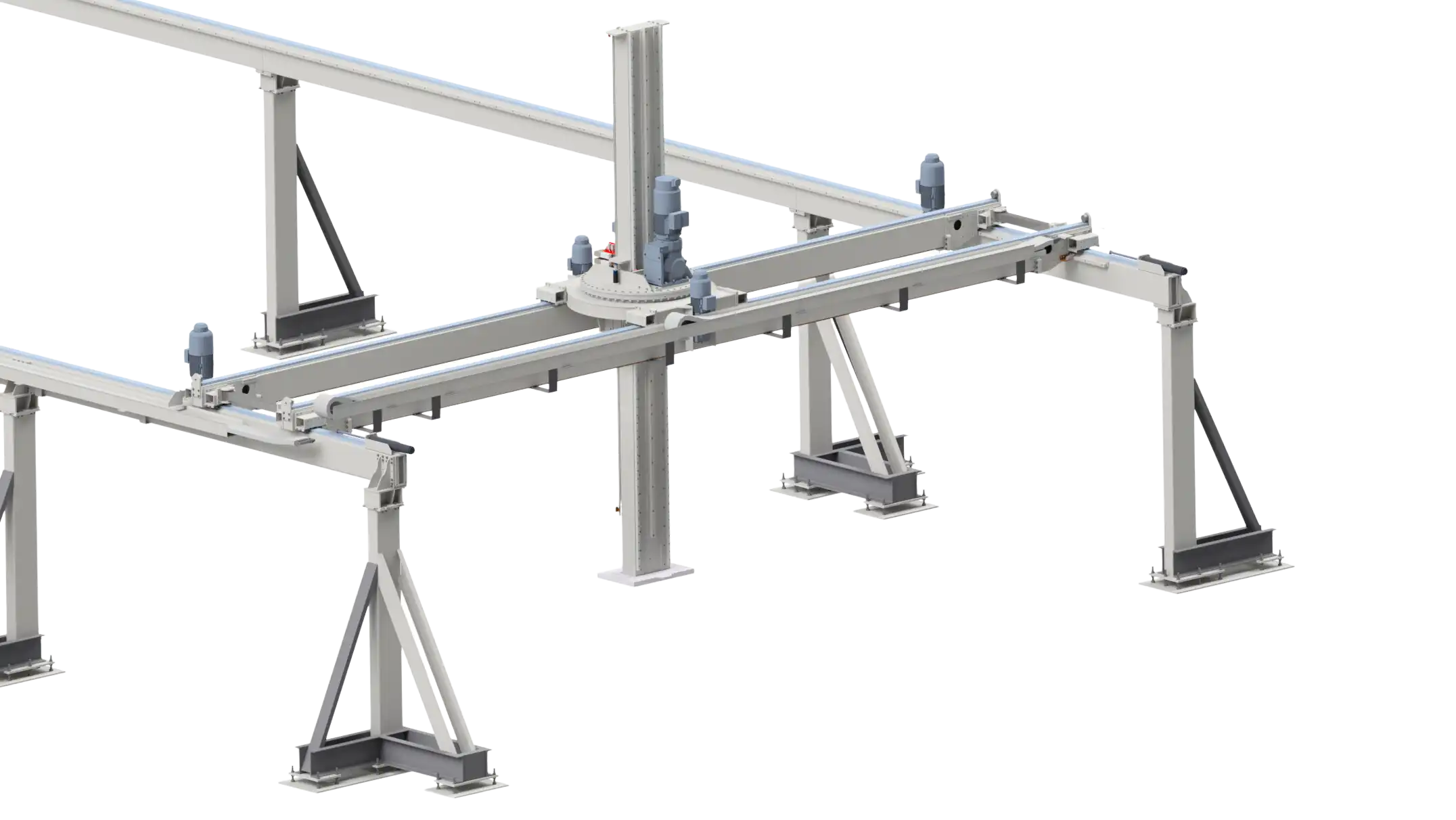

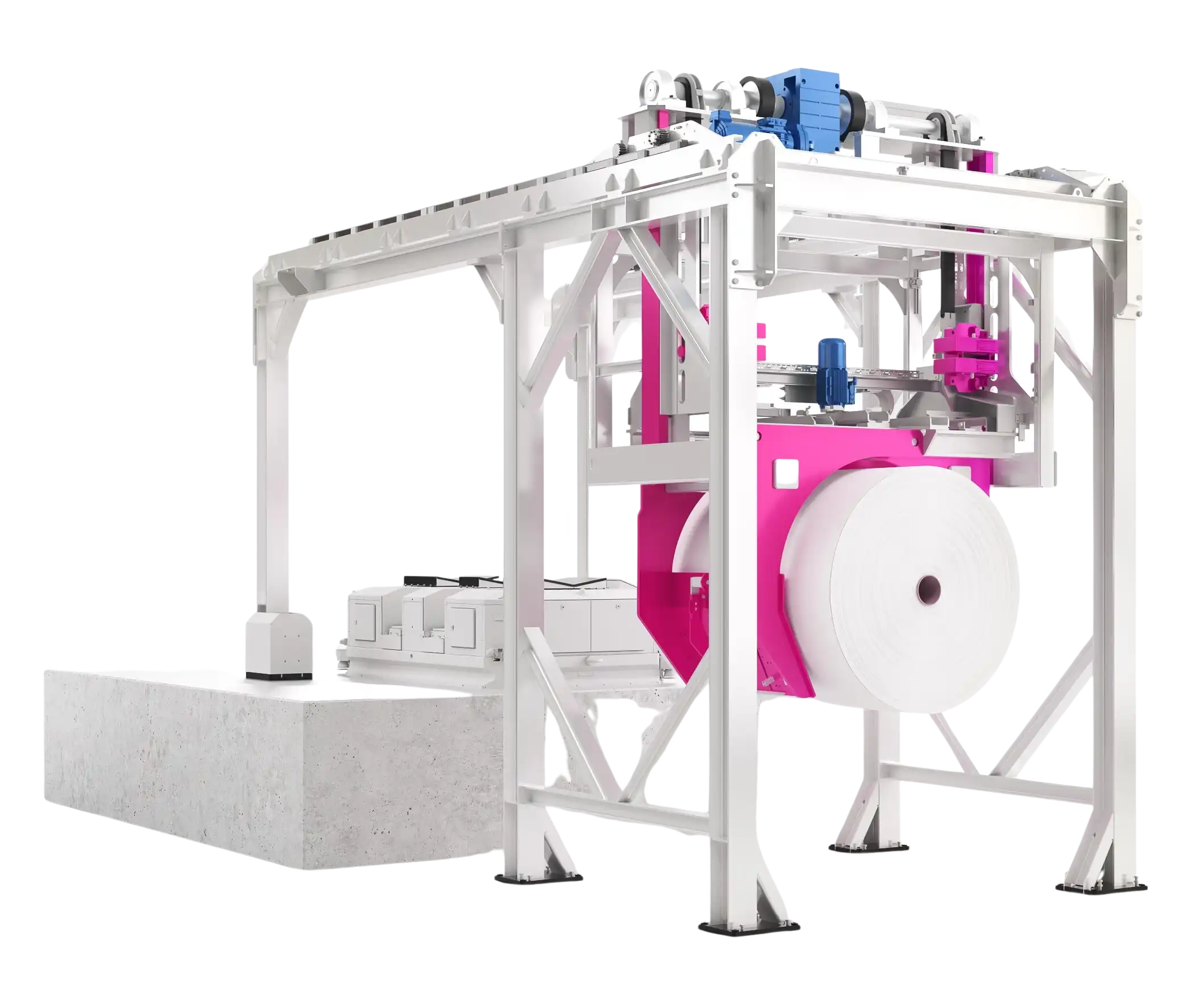

Portals

Our gantry is characterized by its robustness and is particularly suitable as a multi-axis linear system for moving, stacking and separating heavy loads. Whether for wooden pallets, stones or with special grippers – this handling system helps you to optimize your application.

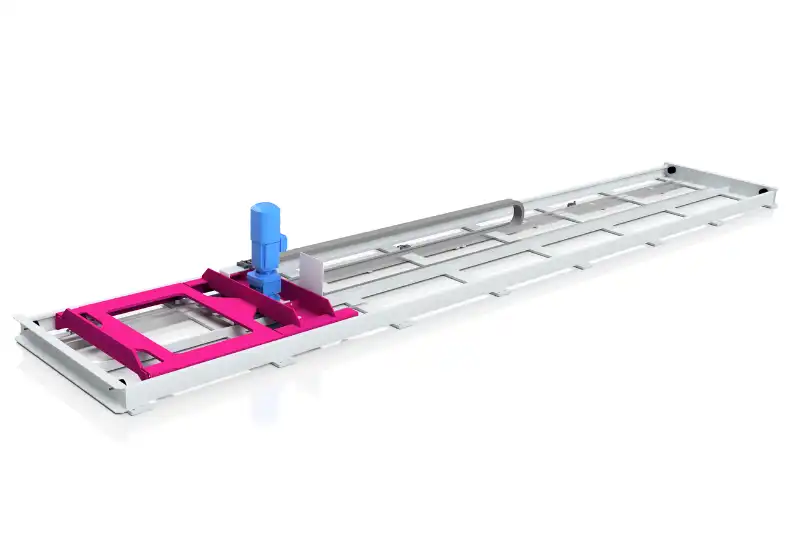

Pallet doubler

Pallet handling for horizontal and vertical applications – with their innovative drive technology, our handling systems have very high dynamics and are characterized by their design for greater compactness.

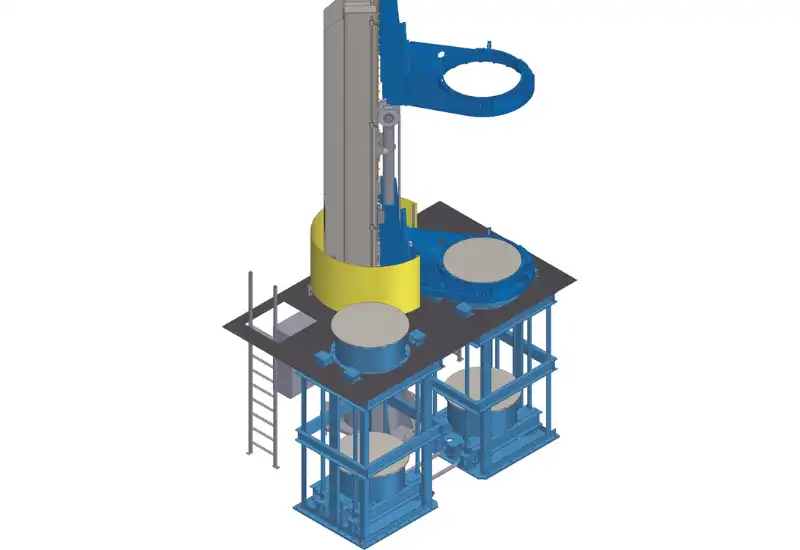

Telescopes

Lifting devices with telescopic forks as a lifting platform, lifting system or stacking crane. Load capacities from 150 kg to 32,000 kg and travel distances of up to 12,000 mm and more. These lifting devices can be used vertically or horizontally and adapt to your lifting equipment.

Special solutions

Our design does not rest until the right solution is found. And if there is no standard product on the market, then we tinker and design ourselves until everything really fits. We are sure to find a solution where many have given up.

What makes ALFATEC handling systems so special?

At ALFATEC, we rely on high-quality materials and precise workmanship to ensure that your handling systems are reliable and durable. Each handling system is individually tailored to the specific requirements of our customers. With our decades of experience, we are ideally prepared for your project. Our experts work closely with you to design handling technology that is as tailored to your current requirements as it is future-proof and adaptable. On request, we can also take care of the maintenance and repair of your handling system.

Maximum safety with maximum efficiency

In order to meet the requirements of modern production and logistics processes, our handling systems are designed to meet the strictest safety standards. Their automated processes not only minimize human error, but also guarantee maximum safety for employees. At the same time, they maximize efficiency through fast, precise and reliable processes. This not only saves time, but also boosts productivity and increases overall throughput. This combination of safety and performance makes our handling systems a reliable choice for companies that care about both operational excellence and the well-being of their workforce.

We are your contact for customized handling systems

We support your project from the very first minute: from briefing, project planning and design to production and commissioning. What’s more, we are always available to provide you with our comprehensive maintenance and services. This gives you the certainty that you have an experienced partner at your side who will find the right solution with flexibility and ingenuity.

The advantages of individual handling systems from ALFATEC

Each system is developed with the highest precision to ensure that even the most demanding tasks can be carried out with the utmost accuracy. Whether for standard applications or specialized tasks, we have the know-how to provide effective handling technology. Maximum efficiency without compromising on safety and ergonomics is a matter of course for us. At ALFATEC, we also attach great importance to sustainable and environmentally friendly products that increase energy efficiency and reduce energy consumption. Our lifting systems are therefore designed in such a way that the energy released during lowering and braking movements is converted and can be used again for lifting loads.

What are handling systems?

When it comes to moving loads of different shapes, sizes and weights in a variety of automated ways, handling systems are required. They enable intelligent movement in industrial manufacturing and transportation processes. Our portfolio includes a wide range of these handling systems: both goods elevators and control operating devices, as well as lifting systems, lifting and moving systems, gantries and telescopes. At ALFATEC, we rely on our modular component system for implementation, which enables us to realize individual solutions according to customer requirements.

Handling systems and their areas of application

Whether in industry, conveyor technology, stone and wood processing, the food industry, research or tool and machine construction. Our handling systems are suitable for a wide range of applications in handling and conveyor technology and ensure a continuous and reliable material flow. Over 10,000 conveyor solutions across all industries speak for themselves.

What components make up handling systems?

Every ALFATEC handling system consists of a sophisticated combination of components that together offer the optimum conveying solution. At the heart of this are our guide rollers and profiles, which, as heavy-duty guide systems, can not only absorb high radial and axial loads, but are also characterized by their robustness and durability. Our handling systems can therefore be ideally integrated into efficient conveyor systems such as belts and roller conveyors. Intelligent control units and flexible drive systems also enable precise handling, while specialized gripper and positioning systems as well as telescopes, in combination with comprehensive control systems, ensure smooth processes.