Automotive lifting system

| High | Safety requirements |

| Installation space | Used efficiently |

| Use | Multi-shift operation |

| Acceleration |

High |

| Speed | High |

Automotive lifting system

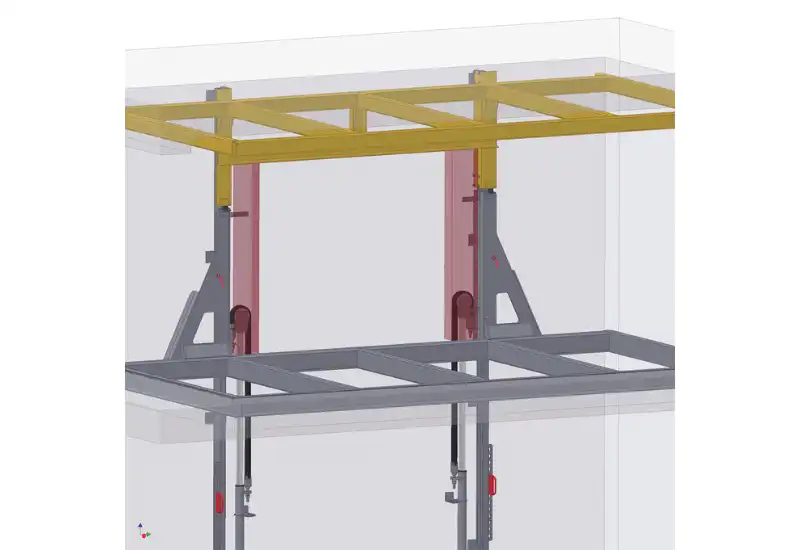

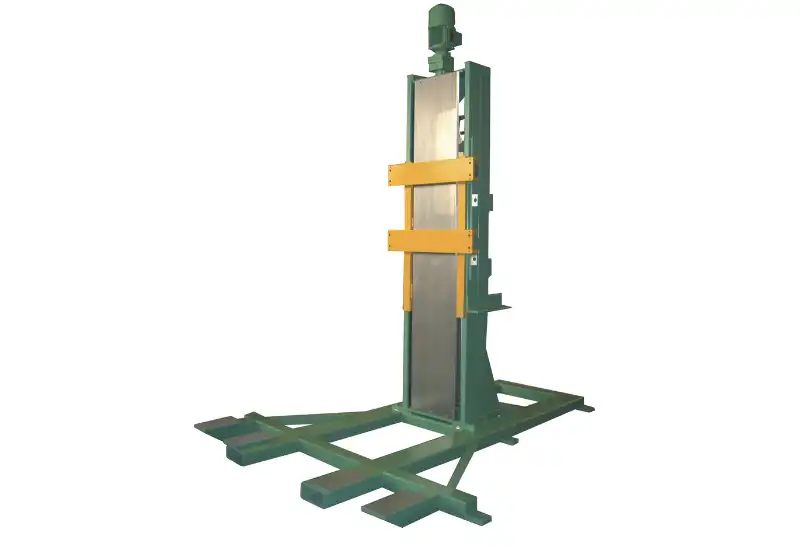

The automotive lifting system is used in a gearbox production facility. The lifting system is approached via an on-site conveyor unit and conveys components weighing 700 kg. The challenge with this project: in order to be able to integrate the lifting system into the existing environment without any problems, the special solution had to be turned into another special solution. Due to the low ceiling height, the drivetrain was not mounted on the lifting system as usual, but deflected several times and mounted on the rear of the lifting mast. This allowed the height of the lift mast to be reduced to a minimum.

System availability must be guaranteed in 3-shift operation, 7 days a week. By using our low-maintenance ALFATEC components, service times can be kept to a minimum.

This type of lifting system is subject to extremely high safety requirements. The lifting system is equipped with several safety components, including

- Counterweight GW

- AWK maintenance chain,

- Position staking ASB.P,

- Fall protection AVS

- and safety staking ABS.

The drive is also redundant thanks to the double design (in stand-by mode). The toothed belt drive does not need to be relubricated and is ideal for the high speed of 1 m/s and the high acceleration of 0.4 m/s². In addition to its ease of maintenance, the lifting system also impresses with the ALFA-Speed rollers and profiles used.

We are your personal partner from the very first minute.