Automotive lifting system stand-alone version

| High | Security requirement |

| Conveyor unit | on-site |

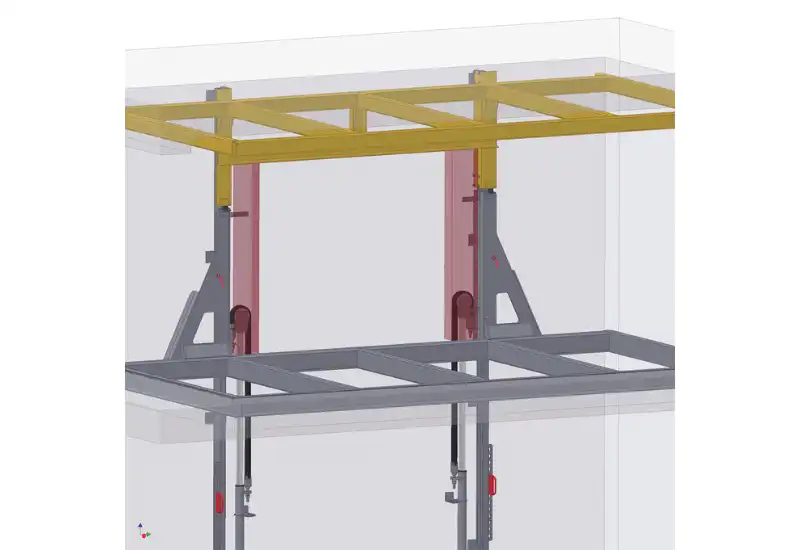

| Screwed | Steel platform at a height of 6 m |

| Version | Stand-alone version |

Automotive lifting system stand-alone version

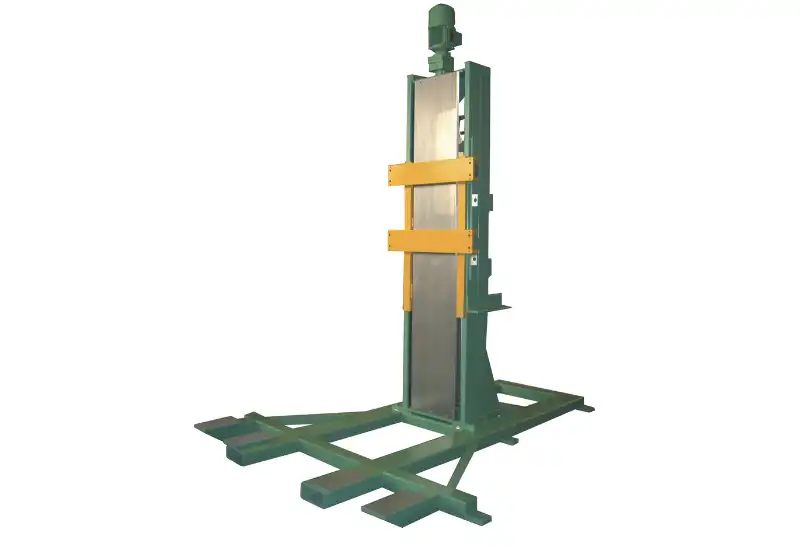

The automotive lifting system is used in an engine production facility. The lifting system is approached via an on-site conveyor unit and conveys motors with a weight of 700 kg. The challenge with this project: The lifting system is bolted as a stand-alone version to a steel platform at a height of 6 meters. This exposes it to higher vibrations, but these are prevented by the clever design.

System availability must be guaranteed in 3-shift operation, 7 days a week. By using our low-maintenance ALFATEC components, service times can be kept to a minimum.

This type of lifting system is subject to extremely high safety requirements. The lifting system is equipped with several safety components, including

- Counterweight GW,

- AWK maintenance chain,

- Position staking ASB.P,

- Fall protection AVS

- and safety staking ABS.

The drive is also redundant thanks to the double design (in stand-by mode). The toothed belt drive does not need to be relubricated and is ideal for the high speed of 1 m/s and the high acceleration of 0.4 m/s². In addition to its ease of maintenance, the lifting system also impresses with the ALFA-Speed rollers and profiles used.

We are your personal partner from the very first minute.