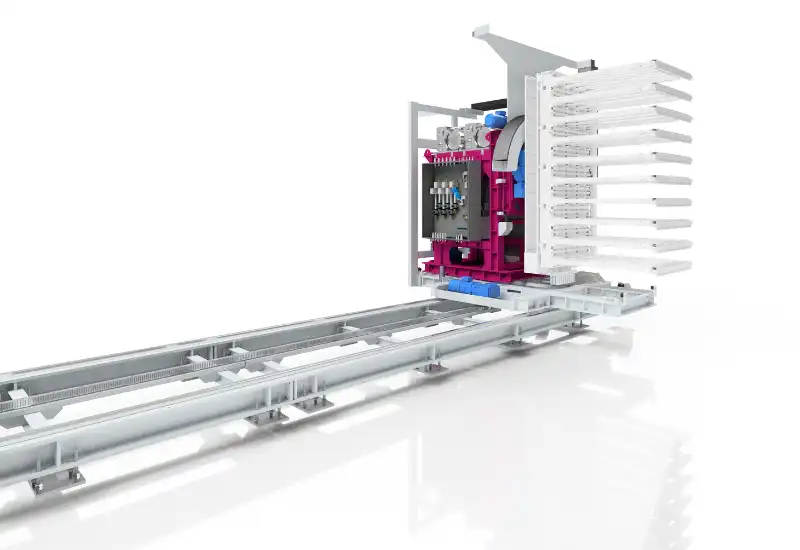

Lifting and moving system for press handling

| Feeding | Automated |

| Axles | 4 |

| Precision | with high load capacity |

| Repeatability | high |

Lifting and moving system for press handling

Automated feeding for press line

To feed two automatic press lines, ALFATEC designed and manufactured a special solution for the lifting and moving systems. A heavy-duty system with four axles was designed to meet customer requirements. Over the total length of 25 m, the vehicle travels at a speed of 1 m/s. The load capacity of 2.25 t is lifted at a lifting speed of 0.1 m/s. The rotation axis rotates in a rotation range of 180°. The customer’s multi-gripper was integrated into the press handling system and flange-mounted to the Y-axis using an adapter plate. With a travel distance of 1.6 m in the Y direction, the workpieces were precisely indexed into the press lines.

A particular challenge is the high positioning accuracy (+/- 0.5 mm) in combination with the extremely high load capacity of 2.25 tons. To achieve a repeat accuracy of +/- 1 mm, the axes were designed as follows:

– X-axis by means of toothed rack and recirculating ball bearing guides

– Y-axis by means of toothed rack and recirculating ball bearing guides

– Z-axis with recirculating ball screw and recirculating ball guides

– C-axis by means of swivel slewing ring

The central lubrication system ensures low-maintenance operation and guarantees high process availability.

We are your personal partner from the very first minute.