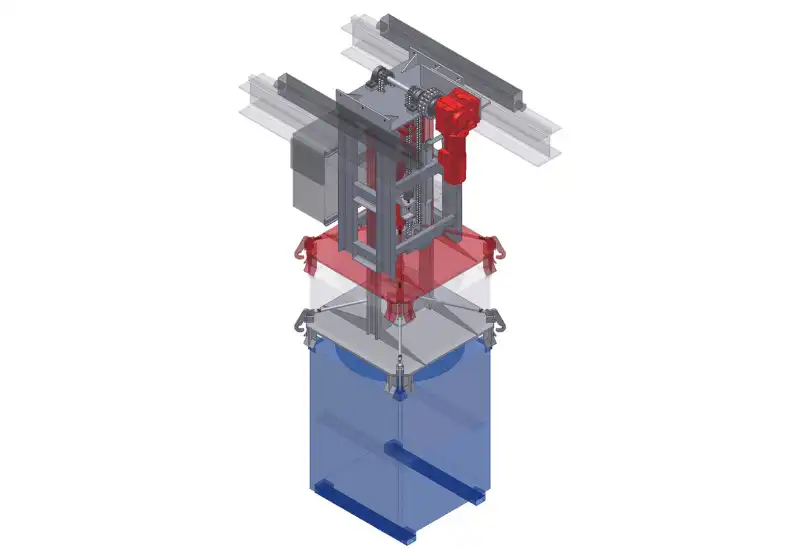

Lifting system with telescope

| Load capacity | 200 kg |

| Route X | 4,200 mm |

| Route Y | 2 x 800 mm |

| Lifting height Z | 1,200 mm |

Lifting system with telescope

Non-destructive material testing

Permanent quality control is particularly important in metal processing. If a metal is processed incorrectly, a small mistake can claim many lives. The digital X-ray system enables the non-destructive testing of cast parts using X-rays. Digital X-ray inspection is used to detect defects that form cavities, such as cracks, doubles, air pockets (so-called blowholes) or gas bubbles.

With a high voltage of 225 kilovolts, the digital X-ray system scans aluminum with a wall thickness of up to 180 millimeters and steel with a wall thickness of up to 40 millimeters. With a room size of approx. 32 m², the X-ray system had to be cut to the millimeter. Due to the lack of statics in the existing room, additional steel beams had to be installed. The X-ray system must also be flexible, as it has to X-ray castings of different sizes. It is also important that the system moves as vibration-free as possible.

The system, which has a stroke of two meters despite its low ceiling height, can X-ray workpieces up to five meters wide, two meters high and two meters deep. A mobile bridge with a rotating mechanism was mounted on a 7.6 by 3.9 meter ceiling-mounted mobile stand. Two vertical telescopes, each with four extensions and a maximum load capacity of 150 kilograms each, are attached to the mechanism’s rotating frame. The X-ray components can be moved on four axes. The mobile bridge with rotating mechanism and telescopes can move from left to right along the ceiling mobile stand (x-axis). The telescopes can be pushed together and apart and rotated along the y-axis. They also move up and down along the z-axis.

The travel speed of all axes is zero to six meters per minute. The system can be rotated at a speed of 7.5 seconds per 45 degrees. This allows the X-ray system to be moved on all sides and individually adapted to the size of the casting to be inspected. The tilting and turning table from ALFATEC can carry castings weighing up to five hundred kilograms. Cameras with sensors guarantee that the telescopic masts do not collide with the test piece.

We are your personal partner from the very first minute.