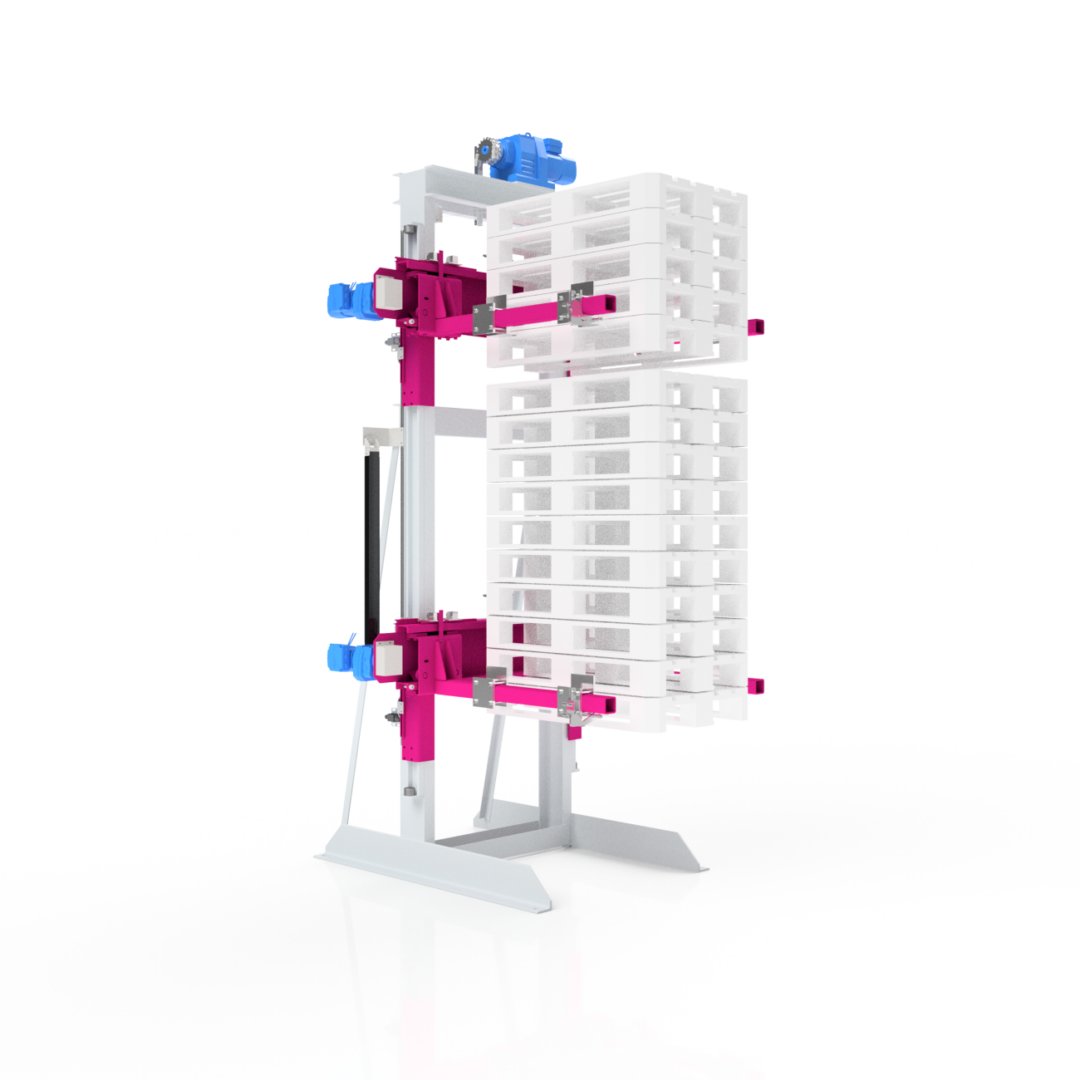

Pallet doppler with telescope

| Mesh boxes | Automated stacking |

| Movements | Lifting, rotating, telescoping |

| Rotary axis | outside center |

| Load capacity | 500 kg |

Pallet doppler with telescope

The ALFATEC stacking device was developed to automatically stack pallet cages on a floor roller with minimum available space.

Our stacking device moves pallet cages with a load capacity of 500 kg. The stacking device is driven by two revolving roller chains. The drive is positioned at the bottom of the lift mast, which enables ergonomic maintenance.

The pallet cages are picked up at a lower lifting height of 350 mm and lifted over a lifting distance of 1,200 mm. The total height of the appliance is 2,300 mm. The telescopic forks cover a telescopic path of 1,200 mm and have a base length of 1,200 mm.

The pallet cages of different heights are supplied via the customer’s roller conveyor. Our stacking device picks up the pallet cages with telescopic forks, turns them 90° and stacks the pallet cages on a floor roller provided. The challenge of limited space was cleverly solved: the lift mast is positioned off-center on the axis of rotation.

The stacking device is located inside the hall and transfers the pallet cages to an area outside the hall. The position of the floor roller is positioned correctly by means of a pneumatic fixing unit. Once all the pallet cages have been stacked, this is displayed to the worker. The worker can enter the safety area, remove the fully stacked floor roller and set an empty floor roller. This achieves a maximum degree of automation for the system.

In order to keep the variance of the system as high as possible, it is also possible to use the stacking device for unstacking the pallet cages and transferring them to the roller conveyor.

We are your personal partner from the very first minute.