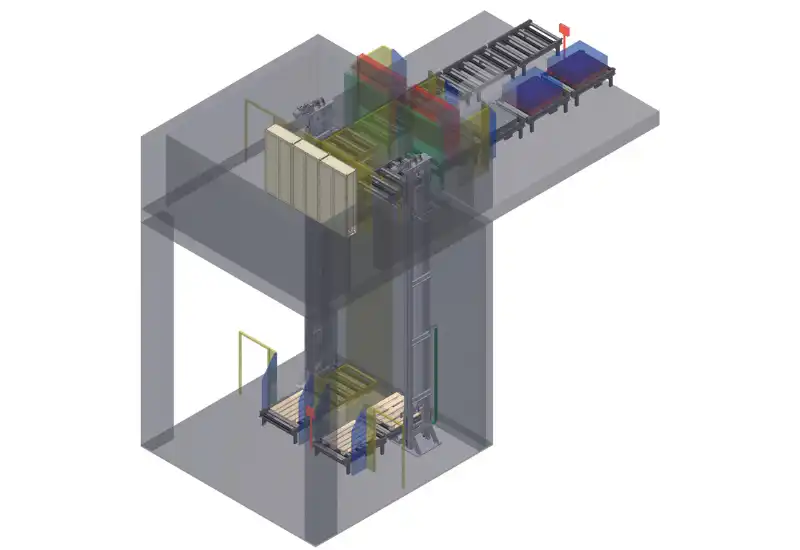

Lifting systems for intralogistics

Our lifting systems for intralogistics guarantee the safe transportation of loads at high acceleration and speed. To maximize the availability of your entire system at the same time, our ALFATEC guide system is optimized for particularly low-maintenance operation.

We combine high speed with maximum availability.

The experience gained from the 10,000 conveyor solutions we have already developed for our customers is incorporated into every one of our lifting systems. We design and build these individually to meet the requirements of each customer and offer you the most efficient solution.

Our lifting systems are designed for maximum safety and efficiency to optimize your intralogistics processes – in all industries from toolmaking and mechanical engineering to stone and wood processing, hospitals and the food industry

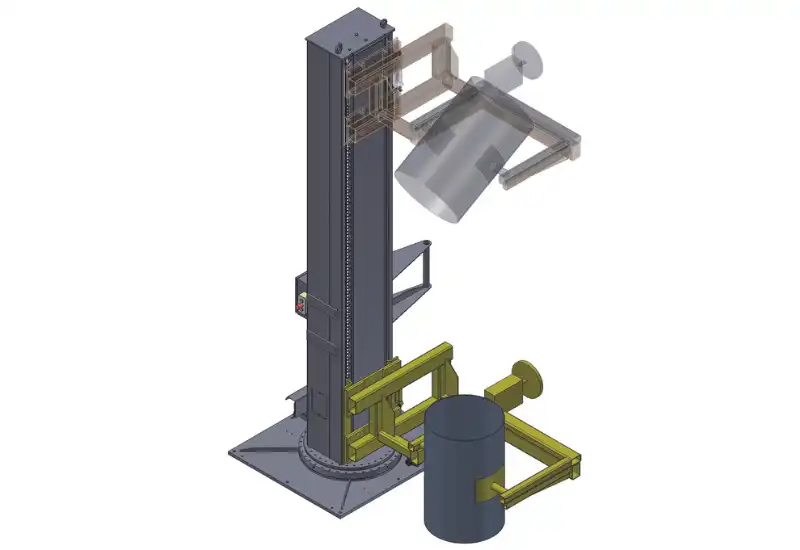

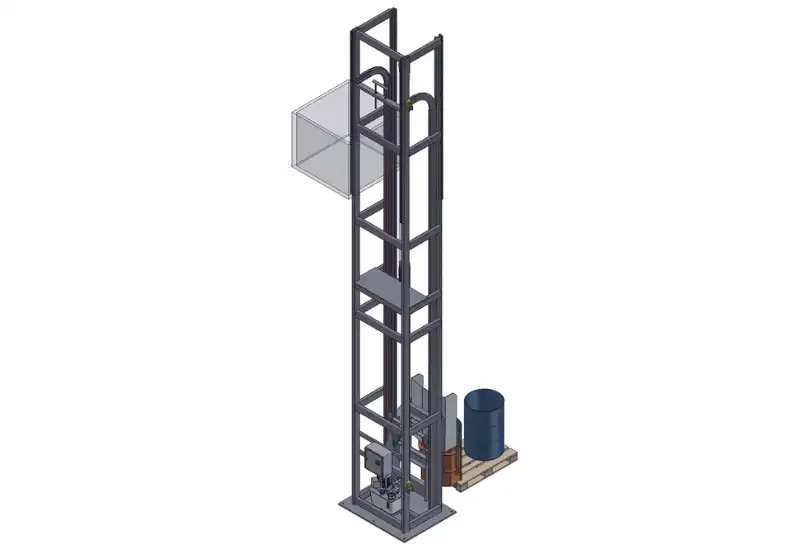

Lifting systems

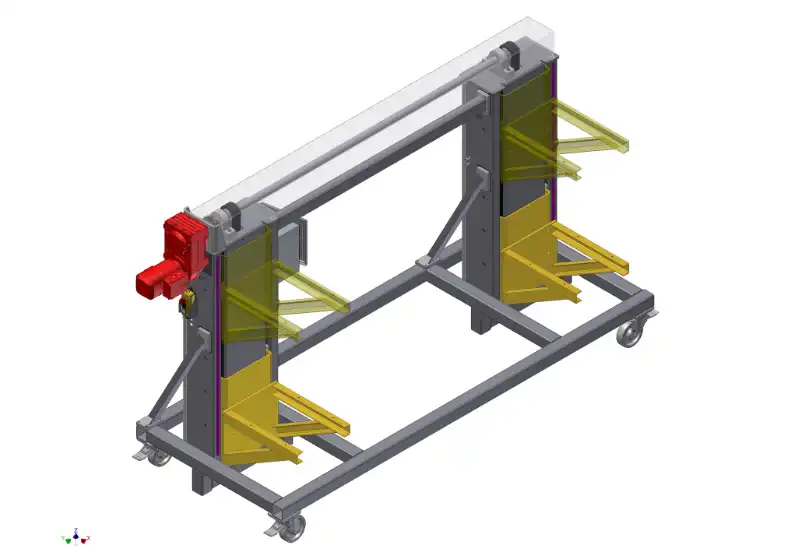

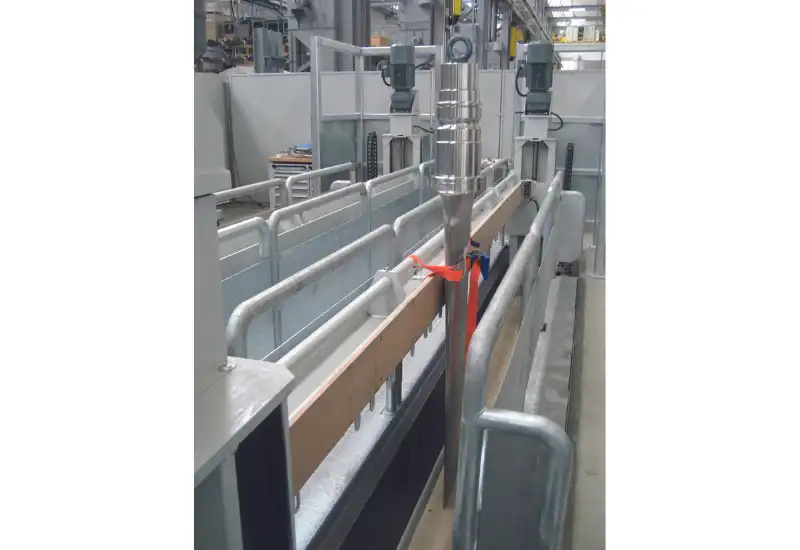

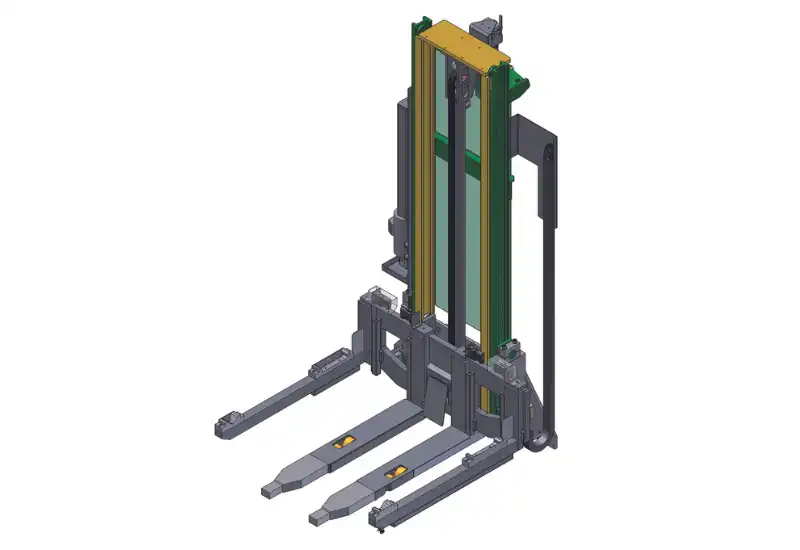

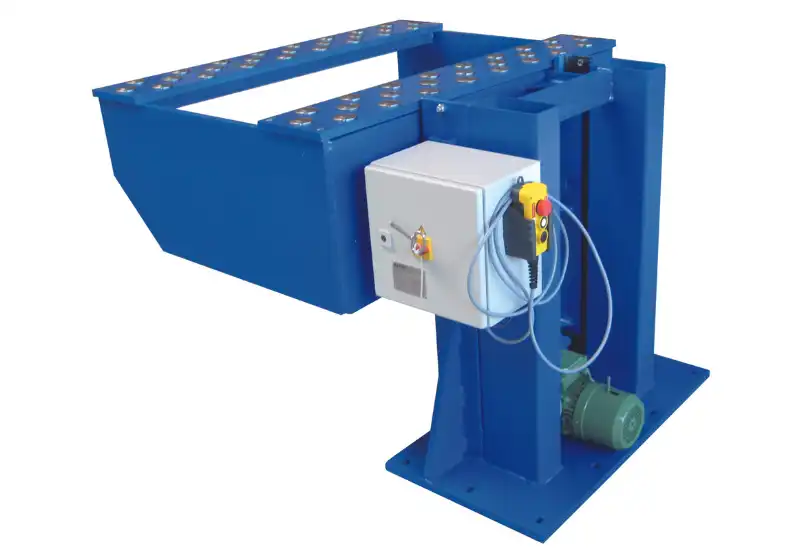

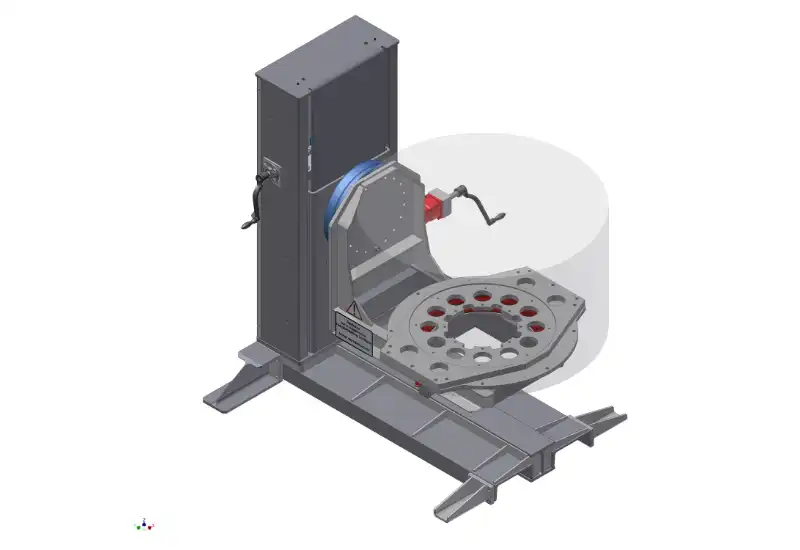

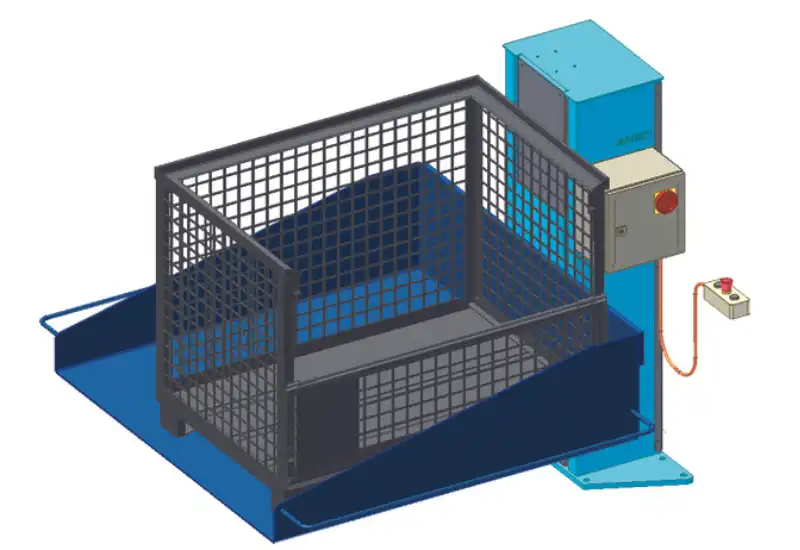

Lifting systems are indispensable for smooth intralogistics processes. Cable lifters, pallet lifters, belt lifters and many other systems ensure that even heavy loads can be moved safely and that production processes remain fluid. That’s why we attach particular importance to maximum efficiency in our lifting systems, without compromising on safety and ergonomics

Automated lifting systems for greater safety and efficiency

The high degree of automation of our stationary lifting systems makes their use not only personnel-efficient, but also particularly safe by avoiding human error. Safety can be further increased with optional safety equipment such as maintenance chains or safety gear.

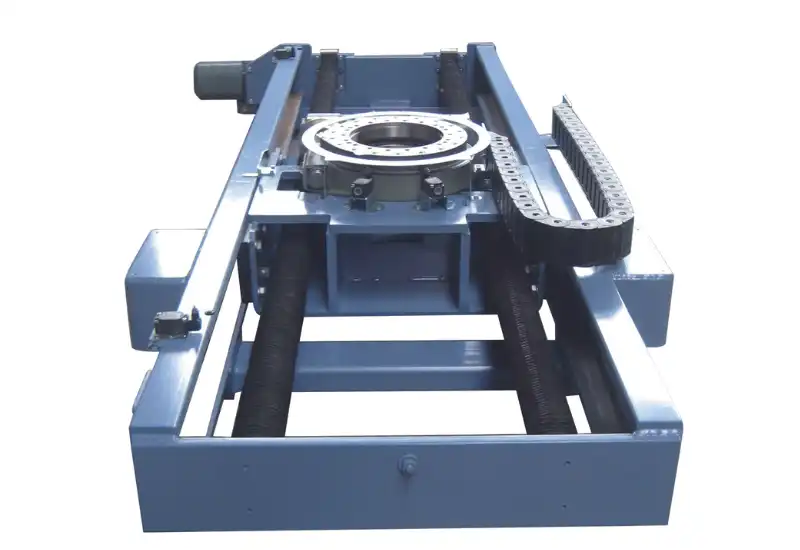

The advanced drive technology, which is optimized for high speeds and acceleration, ensures efficient operation. The

guide rollers

from our company are precisely matched to these requirements, allowing the advantages of our lifting systems to be fully utilized.

Lifting systems: all services from a single source

ALFATEC accompanies your project right from the start. Our customer advisors take the time to understand your project and your requirements. We develop and build a ready-to-use product for you that you can integrate directly into your intralogistics systems. Even after commissioning, we are always there for you when it comes to the maintenance and repair of your lifting system, so that you can always rely on functioning technology.

What makes ALFATEC lifting systems so special?

Every lifting system for intralogistics that leaves our company is individually planned, designed and built according to our customers’ requirements so that it can be optimally adapted to their specific needs. The realization of different lifting heights, gripper systems and much more is no problem. This guarantees maximum efficiency and ergonomics during use.

If none of our lifting systems meet your requirements, we will develop a customized solution from scratch for you. We tinker and develop until we have found a solution. We are only satisfied when you are satisfied.

Are you looking for lifting systems for the automotive industry?

We also offer customized

lifting systems for the automotive industry

. Our solutions have been used there by all well-known manufacturers for many years. Here, too, we rely on individual handling systems that meet all requirements.