Lifting system with integrated chain conveyor

| System | Lifting system |

| Chain conveyor | integrated |

| Solution | turnkey |

| Dead man’s switch | with partial automation |

Lifting system with integrated chain conveyor

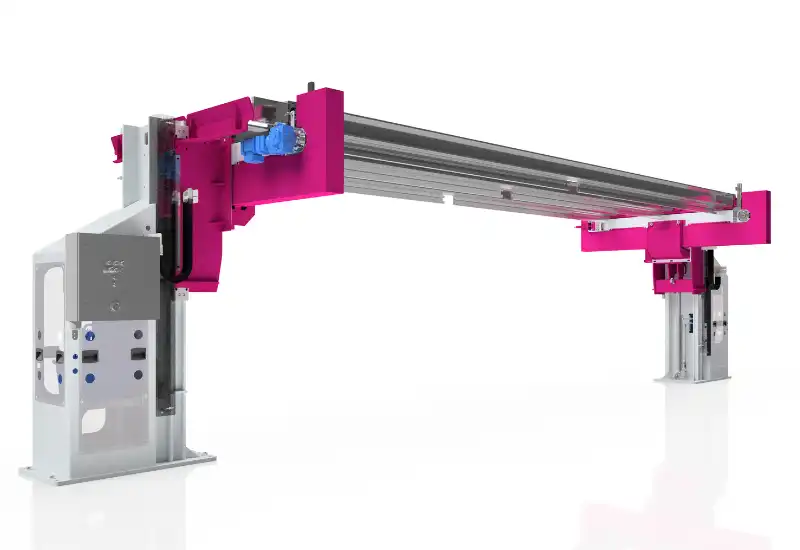

For a manufacturer of anodized aluminum profiles, Alfatec supplied a solution for picking profiles at an ergonomic working height. A semi-automated crane is used to load and unload the beams. Anodized aluminium components hang from the crossbars.

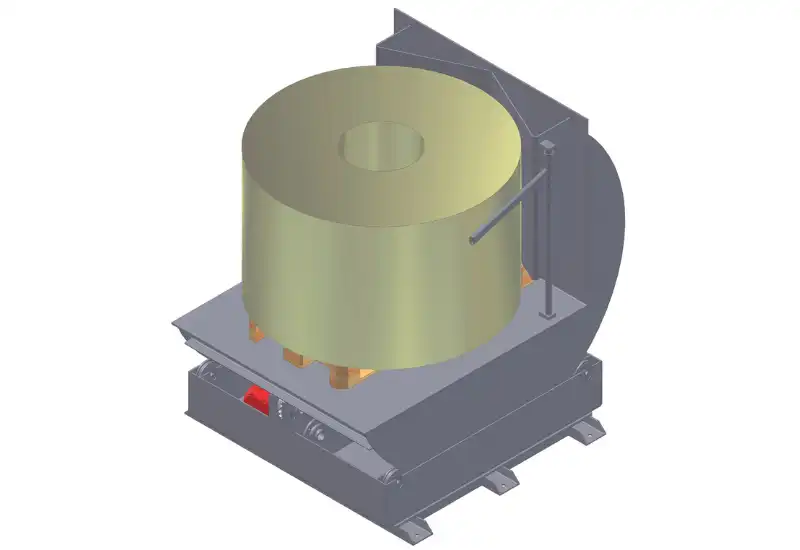

The ALFATEC special solution consists of two lifting masts, each with an integrated chain conveyor. The load capacity is up to 6 tons. The lifting system accommodates up to three lifting beams, which are 8.5 m long. The lifting beams are transported horizontally to the removal station, where the worker raises the lifting beam to an ergonomic working height. The empty lifting beam is picked up by the crane and the worker requests the next lifting beam.

The lower lifting height is 1,940 mm and the upper lifting height is 2,600 mm.

The lift mast is driven hydraulically and the chain conveyors electrically. The lifting system was supplied by ALFATEC with a control system and CE mark: The control concept includes a dead man’s switch with semi-automated pre-positioning. Inclined position monitoring and synchronous operation monitoring are part of the safety concept to ensure safe and ergonomic working at the same time.

We are your personal partner from the very first minute.