Key data for the handling system

| Load capacity | 20,000 kg |

| Swivel range | 90° |

| Includes | Screw jack tables |

| Includes | Capsule intake |

Safety features

Drive type

Requested products

Industries

Contact our experts:

Is that what you need?

Request now without obligation.

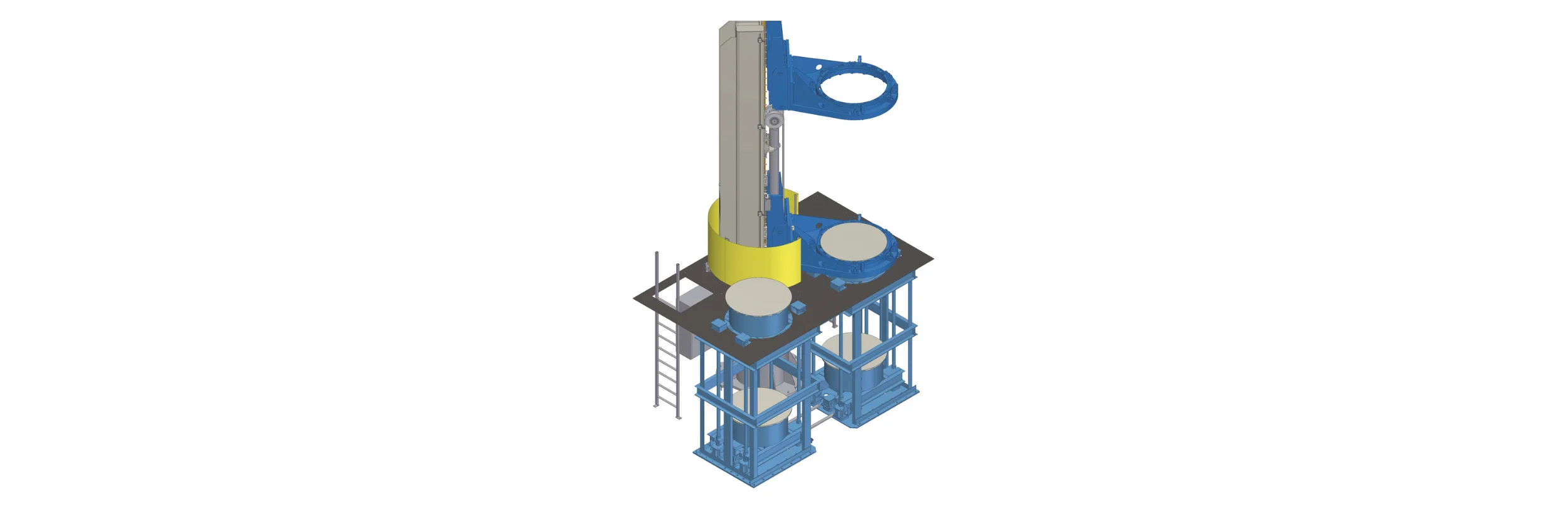

Lift/Swivel Unit Hip Method

Charging stations play a central role in production processes where heavy and often hot workpieces need to be moved. They enable precise, safe and ergonomic handling, even with extreme weights. Thanks to their adaptability, they can be seamlessly integrated into existing production and logistics processes.

HIP process

Bodycote in Magny-Cours, France, refines components for motor racing using the HIP process (hot isostatic pressing) at high temperatures of up to 2500°C and under high pressure. The workpieces are placed on customised workpiece carriers, encapsulated and wrapped in metal foil.

Load and temperatures

Each filled capsule can weigh up to twenty tonnes. The capsules are subjected to isostatic pressure on all sides for several hours and heated in a furnace to up to 2,500 °C. After treatment, the parts cool down to 50 to 60 °C until they arrive at the charging station. Loading and unloading takes place within one hour.

Required internal logistics

The fast processes require efficient internal logistics. Workpieces must be transported, positioned and made available for further processing smoothly, without delays or safety risks.

Looking for a solution like this?

Then send us an inquiry directly and we will get in touch with you to realize exactly the handling system you need.

Charging station from ALFATEC

ALFATEC developed a custom-designed charging station that takes the spatial conditions into account and facilitates the handling of workpieces. The system enables the precise and safe loading and unloading of loads weighing up to twenty tonnes.

System structure

The system is based on two spindle lifting units. On one side, the employee loads the workpiece carrier, while on the other side, the furnace hood is removed. The furnace hoods are transported by an indoor crane.

Lifting and working height

The load carriers can be lowered up to three metres into the ground, enabling employees to work ergonomically at all times.

Space requirements and precision

The system requires only three by five metres of floor space. Sensors monitor the entire process and ensure precise positioning of the workpieces.

Special features

The coordination between the charging station and the indoor crane significantly reduces loading and unloading times. The compact design, ergonomic working height and sensor monitoring ensure efficient, safe and precise operation.

Contact individual contact person

Holger Wenzelburger

Technical Manager

Christoph Stäbler

Managing Director