Key data for the handling system

| Load capacity | 20 tons |

| Drive | Hydraulic |

| Conformity | UL compliant |

Safety features

Drive type

Requested products

Industries

Contact our experts:

Is that what you need?

Request now without obligation.

Lifting System for Galvanising Plant

ALFATEC lifting systems are used in a hot-dip galvanizing plant for loading and unloading black and white goods. A lifting system picks up a traverse from the customer. The crossbars are either fitted with pre-galvanized components (white goods) or with components that are prepared for the zinc bath (black goods).

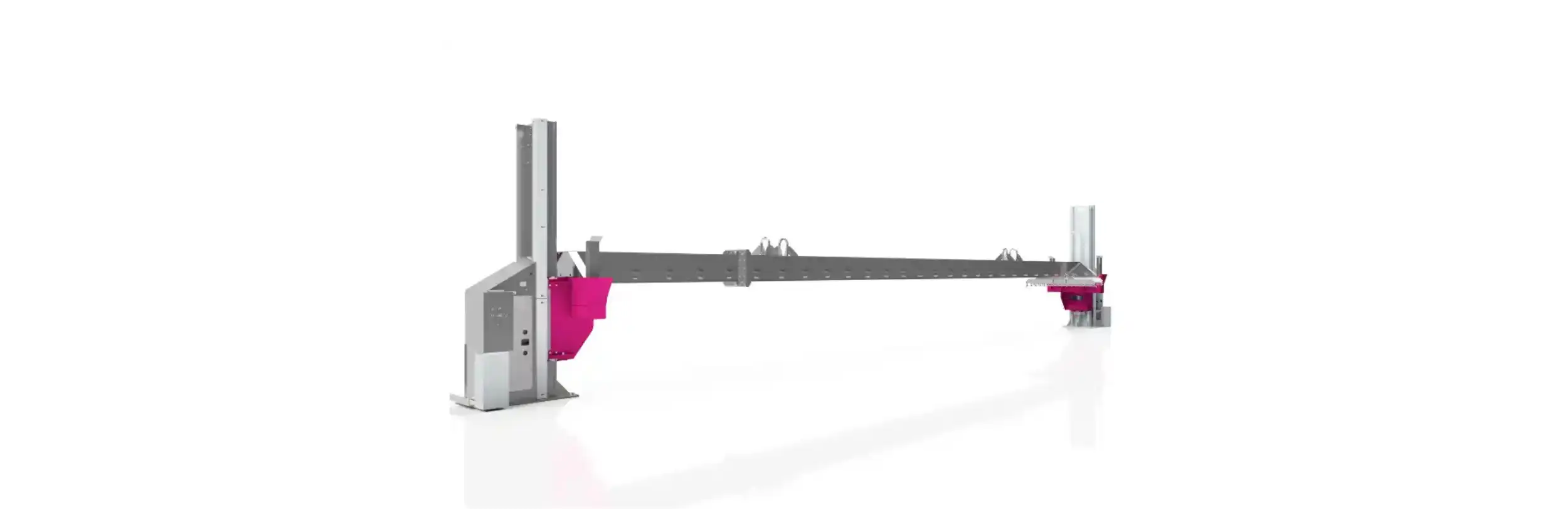

Structure and dimensions of the lifting systems

A total of eight lifting systems were manufactured. A lifting system consists of two lifting columns that are 4.1 m high and approx. 19 m apart. Our lifting systems are tailored to the customer’s lifting beams, which are 18.5 m long and weigh up to 20 tons.

Lifting heights for ergonomic working

The lower lifting height is 1,400 mm and the upper lifting height is 3,600 mm. This enables ergonomic loading and unloading of the crossbeams.

Hydraulic drive with dead man’s control

The lift mast is hydraulically driven. The lifting systems were supplied by ALFATEC complete with controls and UL approval for the USA. To ensure maximum safety for the workers, the control concept was implemented with a dead man’s control system.

Flexible inclination of the lifting columns

The two lifting columns can be deliberately inclined so that the traverse can be fitted with components of different lengths. As an option, it is possible to monitor the inclination electronically. The redundant safety concept ensures safe and ergonomic working at the same time.

Integrated weighing device

The integrated weighing device determines the actual weight of the lifting beam. This is shown to the operator on a display. This determines the zinc application on the components. If required, the determined data can be transferred directly to the customer’s ERP system via an interface. The conventional weighing of components is no longer necessary. This optimizes the entire workflow, which leads to a significant reduction in throughput times.

Contact individual contact person

Holger Wenzelburger

Technical Manager

Christoph Stäbler

Managing Director