Key data for the handling system

| paper roll weight | 4,5 tons |

Safety features

Drive type

Requested products

Industries

Contact our experts:

Is that what you need?

Request now without obligation.

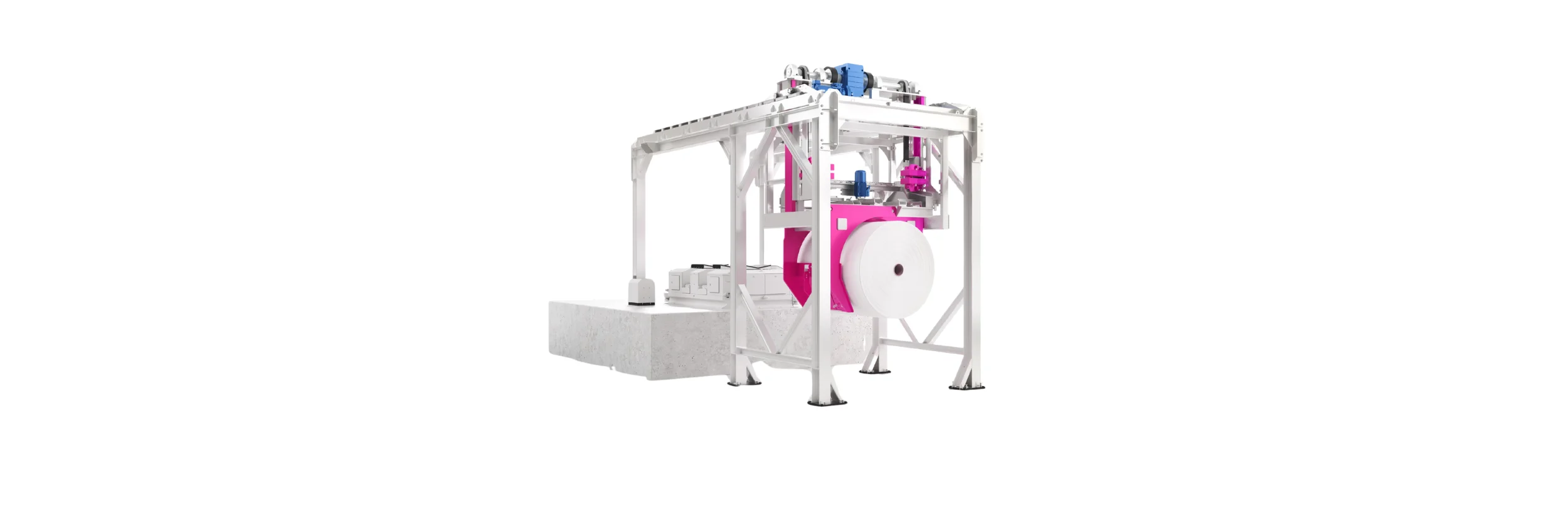

Paper Roll Handling

Lifting and moving heavy loads is part of everyday life in the manufacturing industry and in logistics. The perfect conveyor technology solution was developed for a label manufacturer’s new coating plant for incoming and outgoing goods and at the unpacking station. In this specific situation, the paper rolls required for manufacturing and coating various types of labels can only be delivered in a vertical position. For internal material flow, however, they need to be transported horizontally on an automated guided vehicle (AGV). At first glance, the task appears simple: tilt the upright roll for processing, then return it to a vertical position for outbound delivery.

The real challenge: the paper rolls weigh up to 4.5 tons and have a maximum diameter of 1,550 millimetres and a length of up to 2 metres. Each roll must be safely rotated and reliably transported. What makes handling even more difficult is the restricted installation space and limited height. For a project with such complex requirements, there is no standard solution. Unlike other providers on the market, ALFATEC offers maximum added value: complete conveyor technology for gripping, rotating, lifting, and transferring – all from a single source.

Contact individual contact person

Holger Wenzelburger

Technical Manager

Christoph Stäbler

Managing Director