Information on handling systems

Not possible, does not exist

Over 10,000 conveyor solutions across all sectors: Industry, conveyor technology, stone and wood processing, food industry, research, toolmaking and mechanical engineering. Each solution is individually tailored to the specific needs of our customers.

We are your personal partner from the very first minute. We accompany a project from the briefing through project planning and design to production and commissioning. What’s more, we are always available to provide you with our comprehensive maintenance and services.

In the search for the best, the “cleverest” solution, every task is a new, exciting challenge for us. We learn something new with every project, even after 25 years. We pass on the knowledge we have gained to our customers. This results in new, innovative solutions that keep conveyor technology moving.

Security

ASB.E Position staking Electromechanical

ASB.P Position stakeout prisma pneumatic

ABS safety staking drive shaft Perforated disk

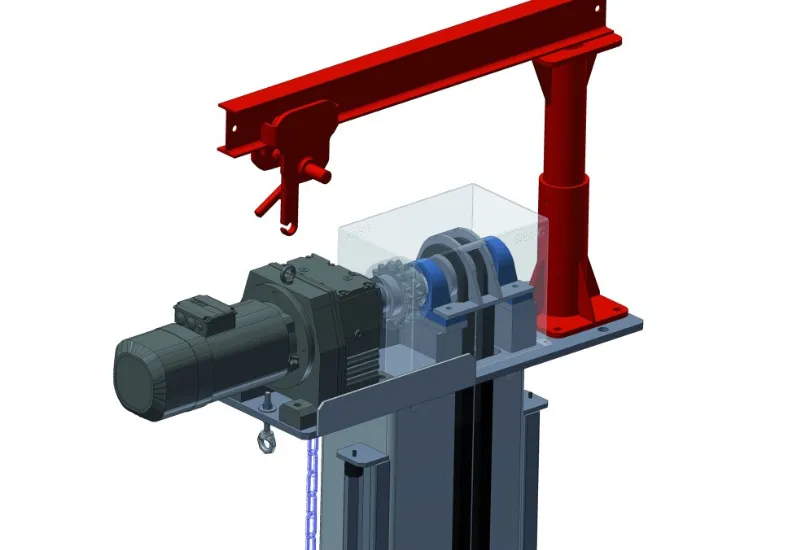

ABG Swivel boom for maintenance/repair

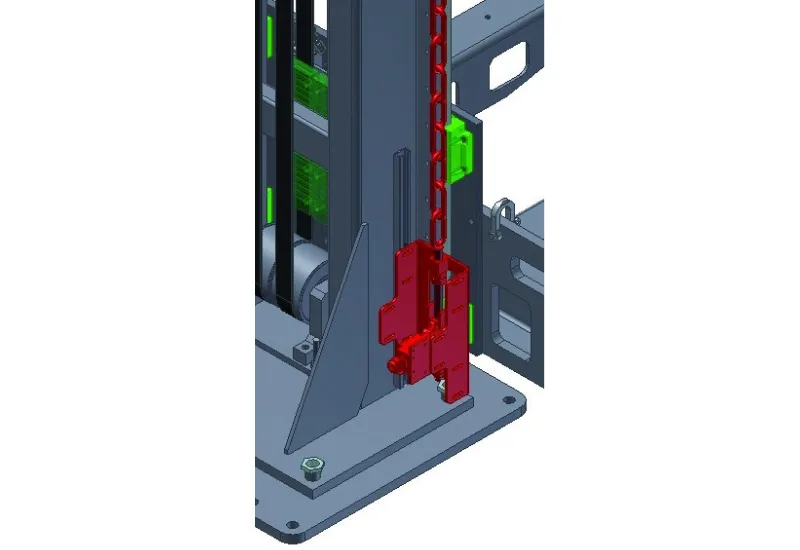

ASB fall protection brake

ABL Stake-out 2-bolt perforated strip

AWK maintenance chain with limit switch

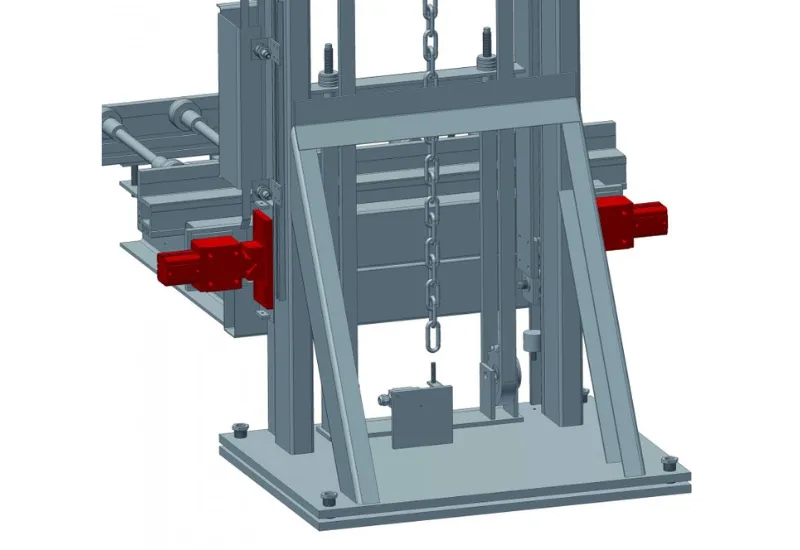

GW Counterweight

KRC chain/belt monitoring

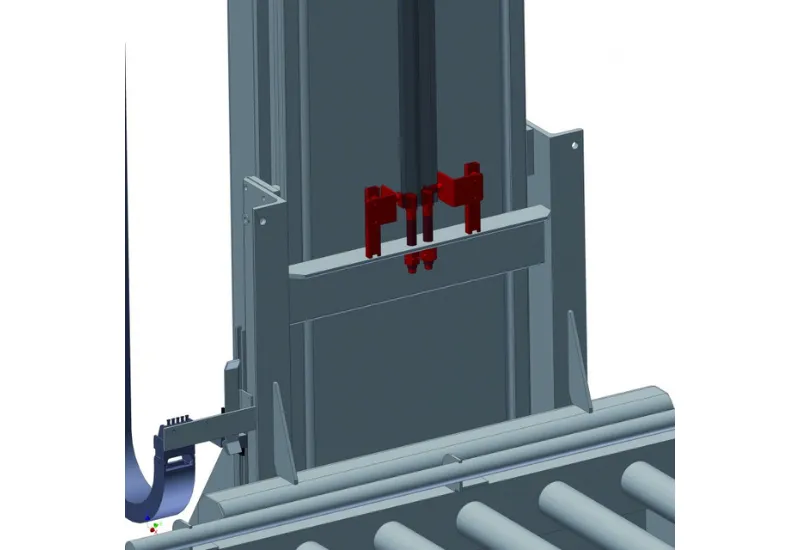

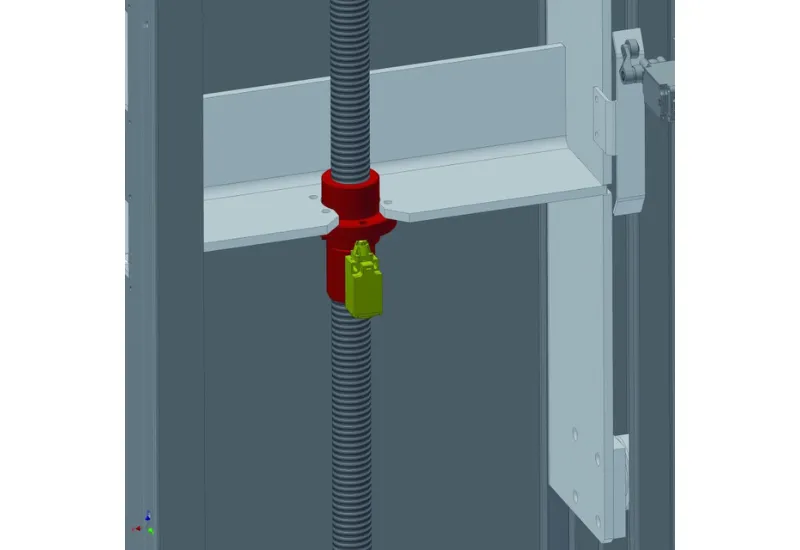

SFM spindle with safety catch nut

AVS fall arrest system with torque converter brake

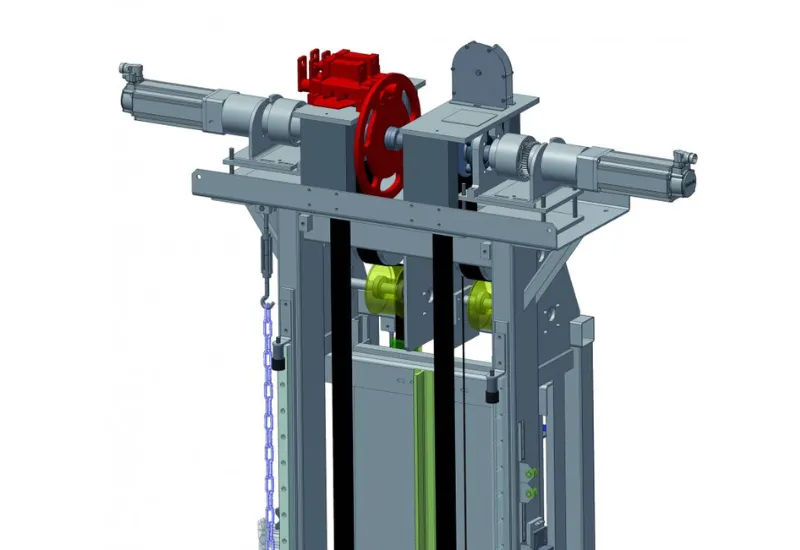

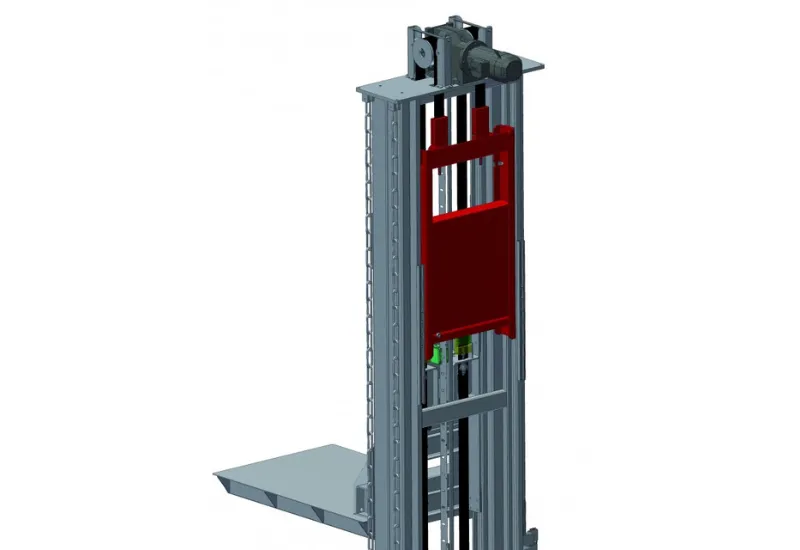

Drives

Chain drive

Rack and pinion drive

Toothed belt drive

Belt drive

Spindle with safety nut

Hydraulic drive

Pneumatic drive

Rope drive

Maintenance – a well-rounded affair

Expert and professional maintenance and services – for your safety!

Handling systems for different load capacities, containers or transport vessels play an important role in production and other processes. They have to function smoothly, because every malfunction costs the company time and money. To ensure smooth operation, ALFATEC offers expert and professional maintenance and services for its handling systems.

Leave nothing to chance and rely on our preventive maintenance service to ensure the longest possible service life for your handling systems.

Modern lifting and conveying systems consist of various components. In daily use, individual components are subjected to different levels of stress. In addition, many other factors such as temperature, contamination and lubrication influence reliable operation. We offer customized maintenance contracts to extend the service life of handling systems and keep them running reliably.

In an annual check, all system components are professionally inspected on site – including visual and functional checks. Electrical or mechanical systems are checked, evaluated and, if necessary, repaired by the trained team. The services also include cleaning services and checking all protective and safety equipment. In the event of a malfunction, this will be rectified immediately and any necessary maintenance and repair work will be initiated after consultation.

A small investment with a big impact

No major investment is required to operate a handling system reliably.

The maintenance contract from ALFATEC ensures optimum functionality by regularly checking and monitoring the handling system.

Your advantages at a glance

- Optimum functionality of the system

- Optimum timing of the maintenance date

- Less administrative work

- Lower spare parts costs

- Reduction in operating and maintenance costs

- Predictable maintenance costs

- Repair work

- Logging of the maintenance steps carried out

We are your personal partner from the very first minute.